Diving Safety

Blueprint for Survival 2.0

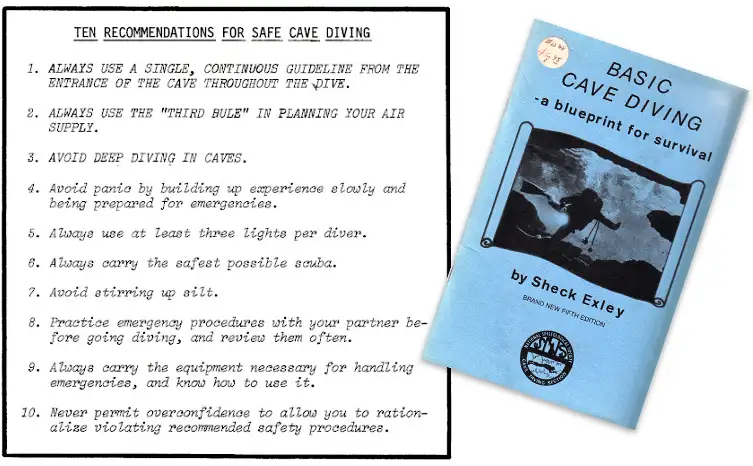

In the early 1990s, when newly named “tech divers” were dying at an alarming rate, the fledgling tech community came together to create a consensus standard of “best practices” modeled after explorer Sheck Exley’s book, Basic Cave Diving—A Blueprint for Survival. The goal was to reduce tech fatalities STAT. The resulting recommendations, which were published in aquaCORPS, are well worth reviewing if you haven’t; and, with a couple of exceptions, like oxygen limits and equipment to protect a diver’s airways, they hold up well nearly 30 years later. Blueprint 2.0 was compiled by Michael Menduno and Capt. Billy Deans.

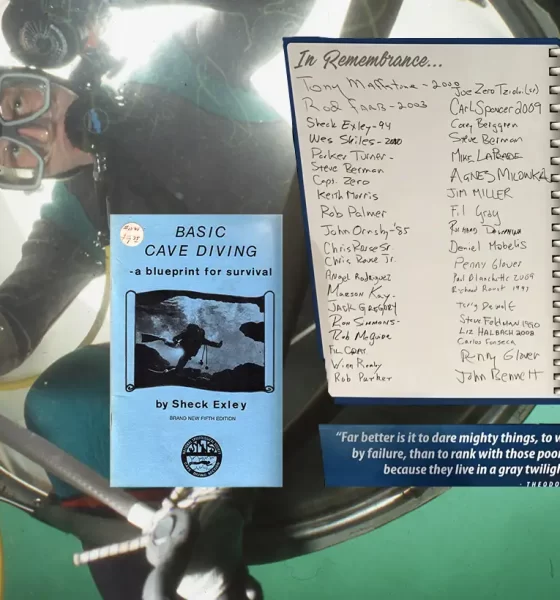

By Michael Menduno & Capt. Billy Deans (1993). Tek.93 and other historical mages courtesy of aquaCORPS archives unless noted. Lead image shows explorer Jim King in a deco habitat, Sheck Exley’s original Blueprint for Survival, and an In Remembrance white board displayed at TEKDive USA 2018 with the names of tech divers who suffered diving fatalities.

🎶 Pre-dive Clicklist:The Who – My Generation 🎶

Note there are FREE DOWNLOADS of aquaCORPS Journal at the bottom of the story!

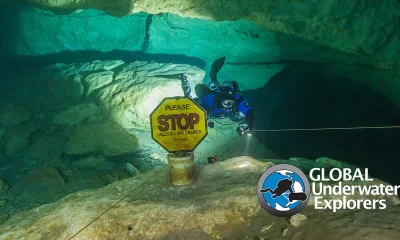

Similar to the commercial and military diving communities, Global Underwater Explorer (GUE) divers rely on formal operational standards to guide their diving operations. Currently, GUE and various DIR communities are the only organizations in sport diving to use operational standards. These should not be confused with various agency’s training standards, which address how classes should be conducted. Today however, the majority of tech divers tend to conform—by varying degrees—to similar gear configuration and protocols. Things were not always this way.

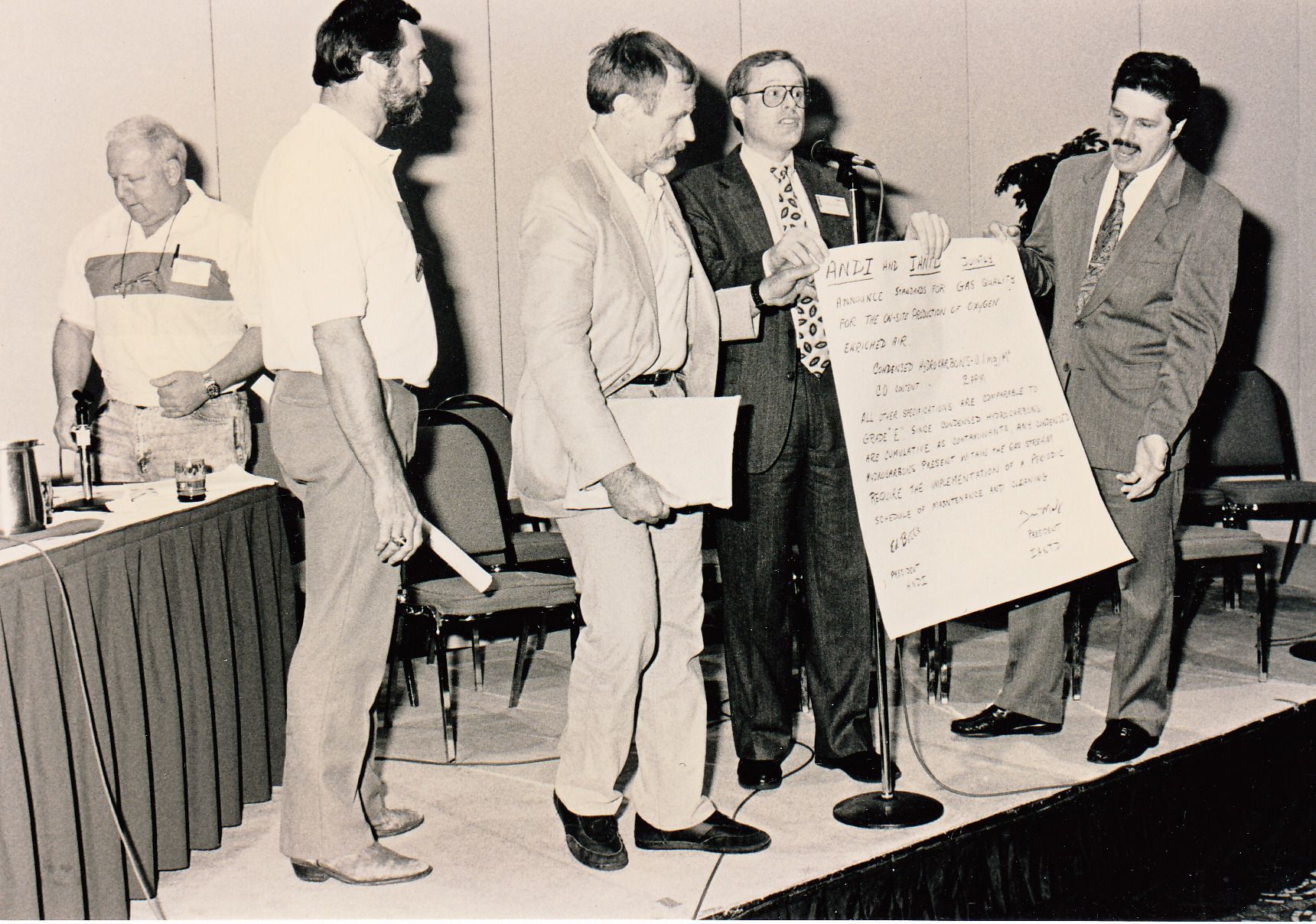

The early days of technical diving were very much a do-it-yourself (DIY) venture. Preliminary training standards had been established by the newly-formed technical training agencies such as American Nitrox Divers, Inc. (ANDI), International Association of Nitrox & Technical Divers (IANTD), and Professional Scuba Association International (PSAI). Technical Diving International (TDI) had not yet been created, nor had GUE. While such standards continued to evolve, there were no agreed-upon guidelines to help direct diving operations.

As a result, and not surprising, there were an alarming number of tech diving fatalities in the late 1980s and early 1990s as divers struggled to figure out safe and reliable protocols for mixed gas diving [See Early Technical Diving Deaths: The aquaCORPS Incident Reports (1992-1996)]. This was a central focus of the first technical diving conference, aquaCORPS’ Tek.93, held in Orlando, Florida in January, 1993 just before the annual Diving Equipment and Marketing Association (DEMA) show.

Originally published in aquaCORPS N6 “Computing”, June 1993, in response to the number of accidents, the guidelines were based on what community leaders perceived as the “best practices” in the technical diving community, and drew heavily from the accident analysis techniques developed by the cave community.

In response to community feedback, we updated and republished the guidelines again aquaCORPS N12 “Survivors” in October 1995. As such they represented a first attempt at a set of community “consensus-standards” for technical diving. Most of them actually stand-up to modern day scrutiny, though a few recommendations such oxygen limits and full face masks have changed. Here then are the original guidelines as they appeared in aquaCORPS Journal. Note they have been edited for grammar and punctuation.—M2

Here are the original guidelines as they appeared in aquaCORPS N12 “Survivors,” OCT 1995. Note they have been edited for grammar and punctuation.

Blueprint For Survival 2.0, October 1995

Though technical training standards have been well established by the American Nitrox Divers, Inc. (ANDI), International Association of Nitrox & Technical Divers (IANTD), Professional Scuba Association (PSA), and Technical Diving International (TDI)—and are continuing to evolve—there is currently no set of agreed upon operational guidelines, i.e. guidelines used to direct diving operations, similar to those developed by the professional and commercial diving communities.

Originally published in aquaCORPS Journal N6 ”Computing” (93 JUN), the guidelines listed below were compiled by Capt. Billy Deans, Key West Diver and Michael Menduno, aquaCORPS with the help of many individuals throughout the community in response to the number of technical-level accidents that were occurring during that period.

They were based on what we perceived as the best practices from the technical diving community, drawing heavily on accident analysis techniques developed by the cave diving community, and were offered as a starting point for the development of community consensus guidelines for technical divers.

Now, two years years later (1995), in light of the tremendous growth in technical diving, and with the majority of the recreational training agencies beginning to use enriched air nitrox, we felt it was necessary to update and republish these guidelines. To do that, we have contacted leaders from around the community—including the heads of the technical training companies—asking for their comments and feedback.

These are incorporated in the following guidelines. As such, this document represents a community perspective which we are pleased to offer to our readership.

Background

About twelve to fifteen years ago in response to the then growing number of fatalities, the cave diving community developed a set of safety principles based on the then-new tool of “accident analysis.” Later refined by pioneer Sheck Exley and elucidated in his book Basic Cave Diving: A Blueprint for Survival (Exley, 1979, 1986), accident analysis is a means of rigorously dissecting an accident into its constituent parts with the goal of determining “what went wrong.” Applying this tool to cave diving, it was discovered that most diving accidents could usually be attributed to a single primary causal factor and typically one or more contributing factors.

What’s more is that these factors could be boiled down into five basic cave diving safety principles: be trained, use a continuous guideline to the surface, manage your gas according to a thirds rule or better, don’t dive deep (on air), and carry at least three lights. A sixth principle, known as “Eternal Vigilance,” states: “Anyone Can Die At Any Time On Any Cave Dive.” Accident analysis of these resulting safety procedures have become the cornerstone of cave diving safety ever since.

Numerous other analyses of sport diving accidents have been conducted following the early cave diving work. In 1989, Mano and Shibayama published a study titled “Aspects of Recent Scuba Diving Accidents” (Mano and Shibayama, 1989), which analyzed 264 fatalities and 319 incidents of decompression illness and arterial gas embolism. According to the authors, over 45% of sport diving fatalities that occurred were due to “reckless diving” or “lack of technique.” Most appear to have been preventable.

In another study, Chowdhury, in affiliation with the National Underwater Data Center (Chowdhury, 1989), conducted an analysis of wreck diving accidents. His conclusions were that 73% of the accidents involving wreck penetration were due to the “lack of a continuous guideline,” while 42% of the fatalities that occurred external to a wreck were due to “out of gas” emergencies.

In 1990, Exley revisited his earlier work in a paper published in Underwater Speleology. Based on the trends in accidents, he concluded that perhaps too much emphasis was being placed on the basic cave diving principles in light of more recent tools and techniques being used by cave divers (e.g., mix technology), and that an expanded list of safety recommendations should be developed for the community.

Exley’s conclusions provided motivation for our original paper. Our approach was to identify and address the factors that could potentially result in diver injury or death by building on cave diving safety principles and practices.

The resulting guidelines are organized into seven categories:

• Requirements

• Training

• Gas Supply

• Gas Mix

• Decompression

• Equipment

• Operations

REQUIREMENTS

The generalized requirements for conducting technical dives were aptly summarized in the acronym AKTEE:

A—Attitude: A proper attitude is essential to conducting technical dives safely. There is no room for recklessness or machismo. Why are you doing this?

K—Knowledge: Without the proper knowledge, there are no options when problems occur.

T—Training: Skills must become second nature—a part of muscle memory.

E—Experience: Experience is exposure- and environmental-specific and takes time to build. Extensive wreck diving experience does not qualify a diver for cave diving and vice versa.

E—Equipment: Every dive requires an appropriate set of tools.

Note that the more challenging the dive and the further the dive goes beyond mainstream sport diving limits, the more risk the diver must accept. No amount of training or equipment will completely mitigate this risk.

TRAINING

Technical training is an ongoing process similar to training for an athletic season or flight training. Continual practice is the key. Completing a formal course is a good first step, but is only a starting point. It does not in itself prepare you to make the dive. Technical diving is a discipline, not a [certification] card.

1. Always be prepared and trained for the dive you plan to conduct. Perform a risk assessment. Ask yourself if you, and your partner, meet the AKTEE criteria and if the dive is worth the risks involved. If the answer is no to either question, call the dive.

2. Review and practice emergency procedures frequently so that they become second nature.

GAS SUPPLY

Ensuring adequate gas supply is the major constraint factor in self-contained diving and represents the single largest risk factor. In particular, planning and carrying adequate gas reserves is critical.

3. Always dive an appropriately redundant breathing system (minimally first and second stage redundancy) in an overhead environment, or when diving in open water beyond 130 ft/40 m. Second stage redundancy and a dive partner is an acceptable redundant system in open water no-stop diving (recreational diving) to 130 ft/40 m in good conditions, though an independent redundant system is recommended for dives deeper than 60 ft/18 m and/or in less than ideal conditions.

4. Pre-plan and calculate the gas required to conduct the dive (gas requirements = planned consumption plus required reserves) and dive your plan. Gas calculations should be based on the most conservative breathing rates of you and your partner. Always dive your bottom gas using at least the Rule of Thirds [turn the dive when one third of your gas is exhausted, leaving two thirds for the exit and reserve] in an overhead environment, or a suitable equivalent in open water, depending on the operation. There should be sufficient reserves for the dive team to exit safely in the event one diver suffers a catastrophic gas loss. For extended open water dives, the consensus seems to be to reach your first decompression stop with one-third of your bottom gas remaining.

5. Plan at least a 33% reserve (1.5 x planned usage) for your decompression gas. Depending on the operation, decompression cylinders should be equipped with redundant regulators.

6. When possible, carry all the gas you will need for the dive unless it can be reliably staged, depending on the operation and environment. Note that the ability to reliably stage gas is one of the major differences between cave and wreck diving. In open water diving the goal is to be “self-sufficient,” to the maximum extent possible. Based on an analysis of gas logistics and depending on the duration of the dive, the self-sufficiency breakeven point for extended open water dives appears to be about 250-300 ft/77-92 m for a two-person team. Open water dives beyond this require an extensive support team and effective communications.

GAS MIX

Mix technology is a tool designed to improve underwater safety and performance when properly applied. The most critical factor in special mix diving is oxygen management, due to the risk of a CNS toxicity convulsion.

7. Always dive the safest possible mix(es) for the dive you plan to conduct.

8. Always analyze, label and log your gas before making a technical dive (even if you think that it’s air). Make sure that you know what you are breathing. Use a contents tag that specifies the type of gas and maximum operating depth. Any cylinder or regulator carrying a potentially hyperoxic gas (PO2=1.6+ at any depth during the dive) should also ideally have “touch ID” capability for zero visibility conditions-see below.

9. Maintain your PO2s at or below 1.45 atm during the working phase of the dive and any time that more than light work is being done, boosting oxygen levels to a maximum of 1.6 atm with care during resting decompression. The community standard today is to run travel and bottom mix at about 1.2-1.45 atm, depending on conditions. Treat PO2s of 1.4 -1.6 atm as a caution zone. Take regular “air breaks” as a safety hedge every 20-25 minutes when breathing oxygen. [ If air is not available, the lowest FO2 travel gas should be used. Some instructors take breaks during the decompression phase of the dive whenever the CNS index exceeds 80%.] Note that the CNS metrics being used today are just guidelines and are not necessarily supported by hard data. As succinctly summarized by Terry Billingsley (Hamilton, 1985): “CNS toxicity is like sand beside the road. If you stay on the road, you won’t get into trouble.”

10. “Just Say No” to nitrox mixes (like air) beyond about 180-200 f/55-61 m or less, depending on the operation and environment. In particular, keep equivalent narcotic depths (END) as shallow as operationally and economically feasible, preferably 150 ft/46 m or less. Note that ANDI limits nitrox (air and EAN) exposures to 165 f/ 50 m. PSA allows very short “non-working” exposures to 240 f/ 72 m and deeper under the supervision of two instructors per student.

DECOMPRESSION

Decompression illness (DCI) is not an accident. It happens and will continue to happen as a predictable part of diving.

11. Always use appropriate and reliable decompression methods and tools for the dive you’re planning to conduct, and be conservative. Carry bailout tables for gas loss scenarios.

12. Whenever possible, utilize a hyperoxic mix for decompression (e.g., oxygen and/or suitable EAN mixes) when conducting a staged decompression exposure. Oxygen at 10 and 20 ft/3 and 6 m stops is preferred in some circles. Air, and to a lesser extent EAN mixes, have been regarded as inefficient at reducing decompression risk (Vann, 1992), though EAN 80 (80% O2, 20% N2) has grown in popularity as it is thought to reduce CNS toxicity risk and can be used at 30 ft/9 m.] Note that just as it is recommended that divers make a safety stop on no-stop dives, some individuals prefer to treat the first (deepest) stop on a mix dive in the same manner and make a short safety stop at least 10 f/3 m deeper than required.

13. Limit oxygen decompression to 20 ft/6 m or less (max. PO2=1.6 atm) and use care. The diver breathing a decompression mix or oxygen should avoid anything that would increase the likelihood of CNS oxygen toxicity, or specifically, anything that might raise the diver’s CO2 level. Use an oxygen regulator “guard” to prevent the accidental use of pure oxygen at depth. Color coding and labeling are insufficient safeguards.

14. Plan for and always be prepared to deal with decompression illness. In particular, have plenty of oxygen immediately available for treatment after any diving operation and know how to use it.

Many people believe that low-cost portable on-site chambers will eventually become the order of the day. In the absence of a chamber, in-water recompression therapy offers promise in technical diving applications, provided the team is equipped and trained to conduct it.

EQUIPMENT

Your equipment is your life support system which allows you to survive in a physiologically hostile environment. Second only in importance to breathing equipment, safety lines and a decompression line system are critical to diver safety.

15. Always use the best possible equipment that is well-maintained and appropriate for the dive you plan to conduct and the environment you’re diving in. Redundancy on all essential subsystems is key. In particular, always carry appropriate emergency equipment and know how to use it, for example: three lights (overhead environment), a decompression reel and lift bags (open water), surface signaling device (open water), and a bailout bottle when diving as a team of one.

16. Always use a continuous guideline when diving in an overhead environment, and/or a decompression line system when conducting extended and/or deep, open-water dives. Note that conducting multilevel, extended open-water hangs without a safety line can be problematic and difficult. It requires skill and practice to perform without compromising the decompression, particularly when using hyperoxic decompression mixes where depth control is critical.

Note that the original set of guidelines (1993) included the following point:

If possible, wear breathing equipment that allows you to survive an underwater convulsion/loss of consciousness, such as a full-face mask system or retaining strap. The use of full-face masks is growing and will likely become a standard for many technical diving applications due to their many advantages.

In practice this point has not stood up in the field. Technical divers have not embraced full-face mask technology, nor have FFMs become a standard. This may change when rebreathers finally hit the market and/or when an effective mask is developed for technical diving applications. In the meantime, practice the effective and conservative use of oxygen management in order to avoid a CNS hit.

OPERATIONS

Technical dives are operations: a project or venture involving planning, preparation, organizational structure, the use of proper equipment, teamwork, competent execution, and the capacity to respond to emergencies immediately and effectively. Diver safety is always the first priority. In terms of support requirements, technical dives fall somewhere in between recreational dives and commercial operations. Note that all dives are operations. In the case of traditional recreational diving, the requirements are minimal.

17. Pre-plan all aspects of the dive you intend to conduct, and dive your plan. Design your operation with the goal of being able to provide immediate and effective assistance to a diver in distress at any point in the dive. In particular, be prepared for the worst, always have plenty of oxygen on hand, and know how to use it. Above all, if you’re not prepared to do it right, don’t do it.

18. Always dive as a team, using surface support personnel, and when appropriate, in-water support divers, whenever possible. In particular, designate an operations manager who is responsible for overseeing diver safety and record keeping. Use a pre-dive checklist to improve your safety. Note that the “buddy system” is not reliable enough for technical diving. A team approach based on individual self-sufficiency and competency is required, though a team of one is acceptable in some circumstances, depending on the operation and environment. Above all, always honor rule number one of team diving: anyone can call the dive at any time for any reason (anyone can die just as easily).

19. Utilize an effective communications system between the dive and support team whenever possible. In the future, wireless communications systems will likely become commonplace.

20. Stay within your comfort zone during all phases of the dive.

21. Remember: YOU, and YOU ALONE, are responsible for your own safety. Never permit overconfidence or peer pressure to allow you to rationalize compromising safety procedures. It could ruin your whole day.

*Definition: Technical diving is a discipline that uses special methods and equipment to improve diver safety and performance enabling the user to conduct dives in environments and perform tasks beyond the scope of traditional recreational diving (i.e., no-stop dives in an open-water environment to 130 ft/40 m; in Europe— limited decompression dives to 165 ft/50 m). For additional information see technical Diver 3.1.

Special thanks to the following individuals and organizations for their interest and input to this work: Jim Baden, Ed Betts, Bernie Chowdhury, John Crea, Sheck Exley, Lalo Fiorelli, Steve Gerrard, Kevin Gurr, Dr. R. W. Bill Hamilton, Lad Handelman, Lamar Hires, Jean-Pierre Imbert, Jim King, Dick Long, Tom Mount, National Association for Cave Diving, National Speleological Society/Cave Diving Section, Tony M. Satterfield, Karl Shreeves, Joel Silverstein, Lee Somers, Dr. Bill Stone, Dr. Richard Vann, and Hal Watts.

NOTES:

- Sheck Exley was one of the key individuals responsible for developing and applying “accident analysis” to cave diving. His book, Basic Cave Diving: A BluePrint for Survival (5th ed., 1986) is required reading for all technical divers. You can obtain a copy from the National Speleological Society/Cave Diving Section, PO Box 950, Branford, FL 32008.

- Betts, E. The Application of Enriched Air Mixtures: The Complete SafeAir User’s Guide. Freeport, NY: American Nitrox Divers Inc., 1992.

- Crea, JT. “Oxygen: the princess of gases,” aquaCORPS Journal 3, Winter 1991, p 28-32.

- Cash C and G Gentile, S Exley & M Snyderman. “Beyond machismo,” Technical Diver 3.2, October 1992, p 20-24.

- Chowdhury, B. Wreck diving analysis: 1970-1990, Report No. URI-SS12-91-22. Kingston, RI: Underwater Accident Center, University of Rhode Island, 1991.

- Exley, S. Basic cave diving: a blueprint for survival. Branford, FL: Cave Diving Section of the National Speleological Society, 1979.

- Exley, S. “Accident analysis revisited,” Underwater Speleology, Winter 1990.

- Fiorelli, L. Proposed NACD training standards and procedures. Soquel, CA: L Fiorelli, 1992.

- Hamilton, RW. “Nitrogen narcosis: its significance in modern diving,” in Nitrogen narcosis, Hamilton RW and KW Kinzer, eds, UMS 64WS(NN)4-26-85. Bethesda, MD: Undersea Medical Society, 1985.

- Leonard, MD and L Hires, compilers. NSS student cave diver workbook. Branford, FL: Cave Diving Section of the National Speleological Society, 1991.

- Mano Y and M Shibayama. “Aspects of recent scuba diving accidents,” Marine Technology Society Journal 23.4, December 1989, pp. 38-41.

- Menduno M. “Safety first: an analysis of recent diving accidents,” technicalDiver 3.2, October 1992, p 3-4, 6-10.

- Mount, T. Technical student manual and workbook. Miami Shores, FL: International Association of Nitrox & Technical Divers, 1993.

- Stone, WC. The Wakulla Springs Project. Derwood, MD: U.S. Deep Wreck Diving Team, 1989.

- Vann, R. “The physiology of mixed gas diving,” talk to the British Sub-Aqua Club, Durham, NC, 1992.

- Watts, H. Advanced deep diving manual. Orlando, FL: Professional Scuba Association, 1991.

Note there are FREE DOWNLOADS of aquaCORPS Journal below!

DIVE DEEPER

InDEPTH: Examining Early Technical Diving Deaths: The aquaCORPS Incident Reports (1992-1996)

InDEPTH:The Early Days of Technical Trimix Diving by Michael Menduno and Dr. RW Bill Hamilton

InDEPTH: The First Helium-based Mix Dives Conducted by Pre-Tech Explorers (1967-1988) by Dr. Christopher Werner.

InDEPTH:aquaCORPS’ Letters to The Editor (1990–1996)

Michael Menduno/M2 is InDEPTH’s Editor-in-Chief and an award-winning journalist and technologist who has written about diving and diving technology for more than 30 years. He coined the term “technical diving.” His magazine “aquaCORPS: The Journal for Technical Diving” (1990-1996) helped usher tech diving into mainstream sports diving, and he produced the first tek.Conferences and Rebreather Forums 1.0 , 2.0 and 4.0. In addition to InDEPTH, Menduno serves as Senior Editor for DAN Europe’s Alert Diver magazine, and writes for DeeperBlue.com. He is a member of the Rebreather Training Council (RTC).

Capt. Bill Deans is a retired critical care nurse and medical flight supervisor. He retired from diving in 1999 after the Los Aves Island Project—a commercial exploration project in Venezuela. Deans was the owner of Key West Diver, Key West, FL —the world’s first technical diving training center. He was a technical instructor trainer, instructor and member of the board of the International Association of Nitrox & Technical Divers (IANTD), and a PADI instructor. He was also President of Deep Sea Technologies, a commercial exploration company that utilized technical diving. Deans is also an Ironman, an active triathlete, and a swim coach.

aquaCORPS #4 MIX was published in JAN92 just before the “Enriched Air Nitrox Workshop,” held prior to DEMA in Houston, Texas. The MIX issue focused on mixed gas technology. It was also the first issue of aquaCORPS that included the tagline, “The Journal for Technical Diving,” a moniker coined by founder and publisher Michael Menduno in 1991. Sponsored by DeeperBlue, Dive Rite, Fourth Element and Global Underwater Explorers

aquaCORPS #5 BENT was published in JAN93 in conjunction with the first technical diving conference, tek.93, held just before the annual DEMA show in Orlando, Florida. The issue focused on decompression illness (DCI) and presented the latest thinking on the theory, classification, treatment, and human factors associated with DCI. Sponsored by DAN Europe.

aquaCORPS #6 COMPUTING was published in JUN93 following aquaCORPS’ first technical diving conference, dubbed tek.93, held in Orlando, Florida in January of that year. The issue focused on dive computing and included interviews with nitrox computer developers Randy Bohrer (Bridge), Kevin Gurr (ACE), Paul Heinmiller (Phoenix), an interview with Karl Huggins (EDGE), and a story about commercial decompression software developed by decompression engineer, JP Imbert. Dr. Bill Hamilton and John Crea reviewed four desktop decompression programs that had recently been launched in the tech diving market. Sponsored by Shearwater Research!

aquaCORPS #7 C2 (Closed Circuit) was published in January 1994 just prior to the 1994 tek.Conference and DEMA show held in New Orleans, LA. The issue focused on rebreather technology, and we planned it as a primer in anticipation of aquaCORPS Rebreather Forum, scheduled to be held in Key West, FL, that coming May. At the time, there were only a few dozen rebreathers in the hands of sport divers. Sponsored by Divesoft