History

SEALAB III (1969): The Divers’ Story

by Kevin Hardy. Photo captions and credits noted.

Reprinted with Permission from the Second Quarter 2024 edition (Vol. 32, #119) of the Historical Diving Society’s Journal of Diving History, www.hds.org. The story has been revised and expanded for this publication.

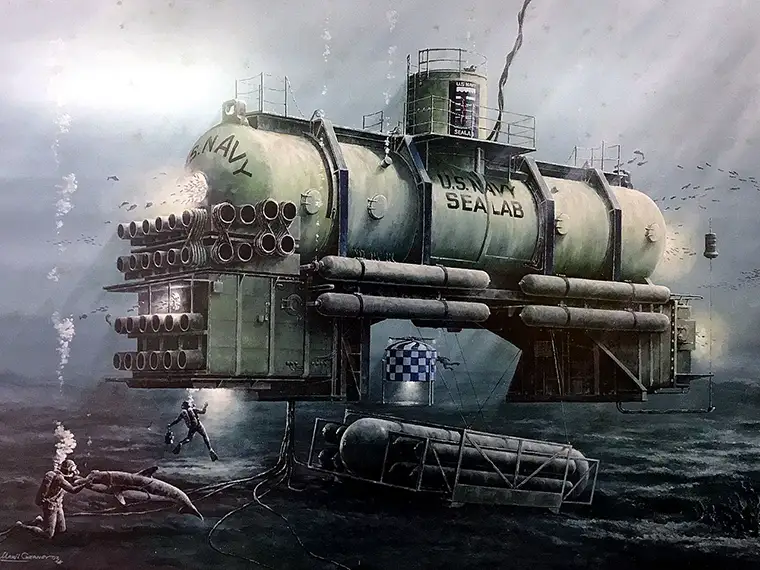

San Clemente, CA,—Sealab III, the US Navy’s third experimental saturation habitat, promised to extend depth capacity to 122 m/400 ft. That was until aquanaut Barry Cannon died shortly after the habitat was lowered to the seafloor. The program, which was already experiencing some major issues, was complicated considerably by Cannon’s tragic death and was shut down.. A Navy Board of Inquiry later determined that Cannon, who was diving a semi-closed rebreather, died of CO2 poisoning resulting from what was presumed to be an empty scrubber canister, making it one of the first highly publicized rebreather fatalities. Now 55-years later, ocean engineer-cum-forensic sleuth Kevin Hardy uncovers the truth in this thorough, suspenseful exposé. Turns out, it wasn’t the rebreather at all!

Background

It is to the enduring honor of the US Navy that their medical dive officers first proposed then advanced the principles of saturation diving. The implications of that breakthrough changed everything about military and commercial diving.

In 1942, Capt. Albert R. Behnke, a USN diving medical officer, first suggested the theory and application of saturation diving techniques to solving caisson’s disease associated with bridge building.

In 1957, USN Diving Medical Doctors George Bond and Robert Workman and Medical Service Officer Walter Mazzone began to test Behnke’s theories for enabling long duration, deep sea diving. The doctors first tested mice, chickens, then goats in recompression chambers. Buoyed by initial success and support from the Office of Naval Research (ONR), they carefully began working with human volunteers. By 1963, encouraged by controlled chamber tests, Bond began making bold plans for a series of open ocean seafloor laboratory experiments. SEALAB was born.

SEALAB I in 1964 was a success. Bond was Principal Investigator (PI). (See JoDH, Vol 22, #79). One team of 4 divers spent 11 days at 59 m/192 ft. It demonstrated the practicality of saturation diving in the open ocean while revealing problems of high humidity, temperature control, and verbal communication in a helium atmosphere.

SEALAB II in 1965 was a success. Bond was PI. (See JoDH, Vol 23, #84). Three teams of 10 divers spent 15 days each at 62 m/205 ft. It demonstrated that ocean-floor habitation can be used to accomplish a wide range of salvage and scientific tasks. No significant short-term physiological changes occurred in the Aquanauts.

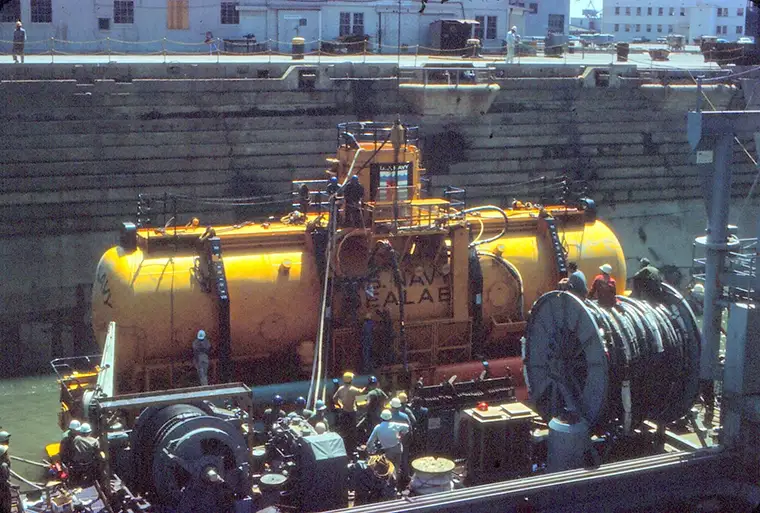

SEALAB III was initially scheduled for completion in summer 1967. Five teams of 9 divers were to spend 12 days each at 122 m/400 ft testing new salvage techniques and conducting oceanographic and fishery studies.

In 1967, Bond wrote of the advancements in saturation diving and the challenges remaining for the USN’s Man-in-the-Sea program in Oceanology International Yearbook, 1968. Bond wrote, “Advances have been made in several areas and present planning provides for … SEALAB III to begin in the last quarter of 1967.”

Following the SEALAB II project off La Jolla Shores in San Diego, Bond was ready to “extend the depth capability to below the 400 ft level.” Bond was becoming familiar with the requirements of deeper depths, citing chamber simulations to 305 m/1,000 ft. He tested “no decompression excursion dives” in sophisticated chambers with divers transitioning from 122m/400 ft to 183 m/600 ft, working for an hour, then returning to 122m/400 ft with no decompression stops. The laboratory tests validated his theory.

In that OI Yearbook report, Bond expected “that new developments will eliminate or minimize the problems of helium speech, inadequate protection provided by wetsuits, the need for the development of torque-free tools for underwater work, and the need for more efficient breathing equipment.” Solutions for helium speech unscrambling were being developed for both inside and outside the habitat.

He noted that “industrial and non-profit organizations are working on the problems of heated wetsuits,” and that “two types of insulated suits, electrically and water heated, will be tested during the experiment.”

He points out the obvious: “The lack of adequate breathing apparatus becomes more crucial as greater depths are reached.” He describes the diving rig for the planned 400 ft deployment: “The Navy has developed a semi-closed SCUBA (Semi-closed Circuit Underwater Breathing Apparatus) rig known as the Mark VIII for testing and evaluation.” (SCUBA in popular terms stands for “Self-Contained Underwater Breathing Apparatus).” In the context of this article, we’ll refer to the Navy’s development as an SCR, a semi-closed rebreather.

Bond then adds a caution: “At greater depths, however, it appears a closed system will be needed.”

Change in command, plus ongoing and broad technical problems, forced a series of postponements. As progress lagged, the mission depth was pushed from 400 ft to 186 m/610 ft in the summer of 1968, just six months prior to scheduled deployment. Bond lamented, “I had become an observer, chronicler, and occasional adviser to the project.”

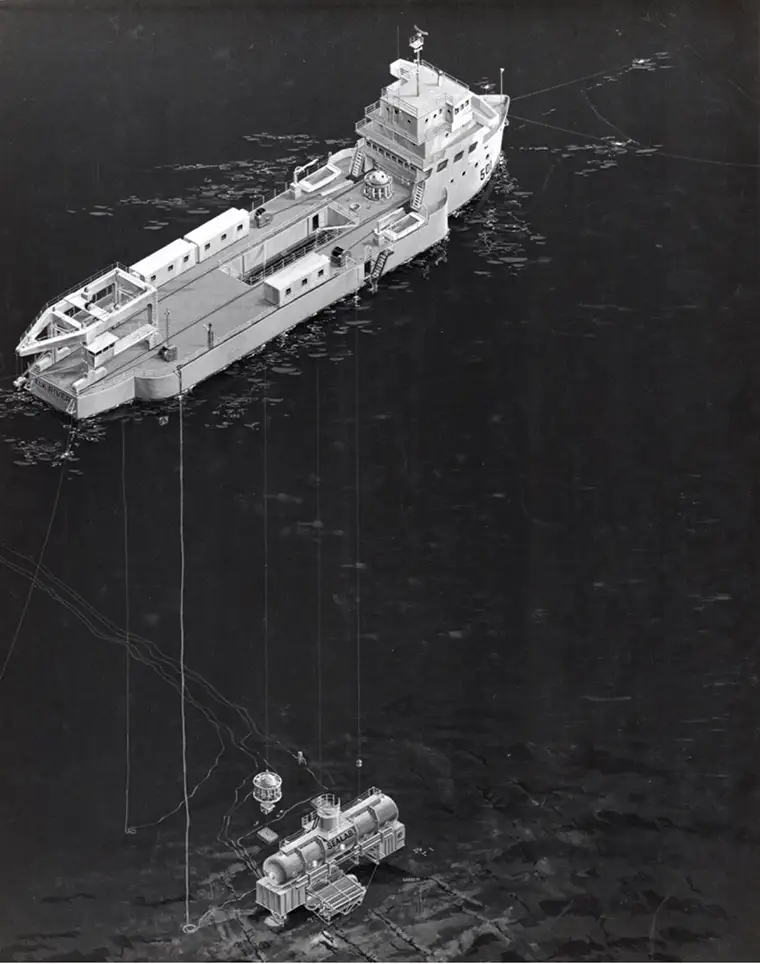

By late October 1968, SEALAB III was floating in the sea off San Clemente Island, tied to the USS Elk River (IX-501). Continued problems forced additional delays, and Bond wrote in his SEALAB Chronicles, “Long ago we abandoned hopes of a visit with our families on Thanksgiving, Christmas, or New Years. Even so, morale is high. Whatever the Aquanauts may lack, it is certainly not a sense of humor.”

On December 1, 1968, a representative of the Deep Submergence Systems Project (DSSP) flew out from Washington, DC to assess the situation and decide what actions should be taken next. Troubled by continued delays and system failures and their impacts on other projects, with the habitat and surface support ship at sea, the DSSP directed deployment to be made on February 15, 1969.

It didn’t go well.

In preparation for SEALAB III, 60 divers trained, 45 divers were assigned to 5 dive teams, 4 men rode PTC-2 (Personnel Transfer Capsule-2) to 610 ft twice, 3 emerged, 2 touched the habitat on the seafloor during two dives that lasted between 7 and 15 minutes, and one of them died.

What went so wrong right from the start?

US Navy Board of Inquiry

The US Navy convened a formal Board of Inquiry (BOI) after the death of civilian Aquanaut Berry Cannon, electronics engineer with the US Navy Mine Defense Laboratory (Panama City, FL). On the Board of Inquiry were Capt. John D. Chase, Capt. Tor Richter (Medical Corps), and Cmdr. William R. Liebold.

At the same time in San Diego, another BOI was reviewing the capture of the USS Pueblo by North Korea. It was a bad news cycle for the USN.

The SEALAB III BOI was looking for a single point of failure. Initially it was attributed to Cannon himself, reporting he had a heart attack. Then it was claimed a CO2 scrubber canister was left unfilled (out of negligence) and Cannon died of CO2 poisoning. That conclusion was not supported by autopsy as the toxicologist’s report of tracheal air was performed many hours after the accident, and if based on pathology findings alone, no causation could have been determined. It was also variously suggested that an unnamed “helper” made a mistake, or an unnamed disgruntled contractor was committing acts of sabotage.

The SEALAB III BOI chose to focus on the empty CO2 scrubber canister theory.

One of four Mark IX (a Mark VIII modified for use from the PTC) semi-closed rebreathers was believed to have had an empty CO2 absorbent canister after the second dive. It was not established that this specific unit was worn by Cannon nor how it was emptied. Reasonable alternative explanations for one being empty were apparently not of interest to the BOI, including that three of them had been left outside of the PTC in the urgency to return to the surface, and were dangling 100 ft below the PTC on ascent.

Nevertheless, the BOI ultimately established CO2 poisoning as the official cause of death.

The BOI then placed the sole blame on an enlisted man, Senior Chief Torpedoman Paul “P.A.” Wells, a decorated World War II Marine Corps veteran. There was talk of court martial. He was invited to leave the service. Wells carried the burden of shame until the day he died.

Capt. George F. Bond wrote in his journal, “Not one of us believed that Paul Wells would ever load an empty canister into a Mk IX rig.” And again, “To a man, we were certain that Paul Wells had made no mistake when he loaded and certified the diving gear.” That sentiment is repeated adamantly by every Aquanaut this author has spoken with about this topic.

To this day, that one diver was killed and another diver was blamed has never set well with the Aquanauts. Warrant Officer Robert A. Barth, Aquanaut #1, wrote, “We lost two good divers that day, Berry Cannon and Paul Wells.”

New Evidence, New Story

In the fullness of time, logs, journals, and reports by those directly involved in the SEALAB III habitat have come to light. In addition, new in-water hazards have been identified.

Like an alternate camera angle on a contested football play, together they tell a different story—a fuller and more complete story—than we’ve heard until this accounting of facts.

Now, almost six decades since that fateful day, we have the SEALAB III Diver’s Story as told by the men below the keel, the divers themselves, and placed here in print as they want it told.

The SEALAB III Diver’s Story is substantially different from the official SEALAB III BOI story.

The old story claimed one man failed to fill one canister with CO2 absorbent, and the entire Man-in-the-Sea program collapsed because of it.

There is now a strong argument for a newer, better, more cohesive, and more accurate story by the team of divers who were there.

Leadership

John Craven, head of the USN’s Deep Submergence Systems Project (DSSP) of which SEALAB had become a part, claimed SEALAB III “was plagued with strange failures at the very start of operations.”

Bond had a clearer assessment: “…Of the thousand-odd people involved with the new experiment, only two naval officers had previous experience with the habitat and with saturation diving procedures—Walt Mazzone and I. We were vastly outnumbered by well-meaning persons who had acquired sudden intelligence of matters that had taken Walt and I our entire naval careers to develop. I was startled to find that the records of previous SEALABs, meticulously maintained, were generally ignored. It is difficult to pinpoint a given source of incompetence, but SEALAB III, scheduled for completion in 1966, was stalled in its tracks.”

Bond continued, “We had too long been delayed by unrealistic planning, constantly revised documentation, and arbitrary changes that were not always passed on to the three hundred-odd personnel.”

Helium

The US Navy began experimenting with helium in diving mixtures in 1924. It used heliox during the USS Squalus salvage operation in 1939. There was history to draw upon.

The noble helium atom is smaller than the diatomic hydrogen molecule. Ocean engineers are familiar with the helium leak detector. “Helium is an elusive and pervasive gas that will leak into and out of any enclosed cavity,” said Bond.

“Although almost every error of design and fabrication that could be made had in fact emerged in the SEALAB III habitat, we also were at fault for failing to impress on each of our contractors that they must design components that could cope with helium under very high pressures. Quality control was left to the vendors without supervision. The vendors did not do their jobs and we were constantly ignorant of the fact,” concluded Bond.

In addition, helium has a thermal conductivity 5.8 times that of air. The increased gas density of helium at 18.5 ATA pulls proportionally more heat out of a diver’s body. Hypothermia is a grave danger.

Helium became the root problem on deployment.

Contractors

The project begins with a head start. The fully tested SEALAB II habitat was to be modified into the SEALAB III habitat. Budgets were increased 10 times to $15 million. Deep pockets lure government contractors. Unfortunately, oversight and Quality Conformance (QC) were undisciplined. The project went $3 million dollars over budget and fell 18 months behind.

Wrote Bond, “In light of our past experience, I am persuaded that most of our hardware contractors actually believed their own advertisements, which guarantee performance of helium unscramblers, thermal protective suits, diver communication devices, helium reclaim systems, and, above all, underwater connectors.

“Even worse is the Department of Defense (DoD) policy of forgiving and forgetting performance failures of the same contractors that have let us down time and again.”

Bad Moon Rising

Aquanaut John Kleckner recalls that half of the divers being assigned to the five Aquanaut teams had never made a SAT dive before. Their ability to physically adapt and mentally perform under pressure was unknown.

Questions are raised about the quality of work done at Hunters Point Naval Shipyard.

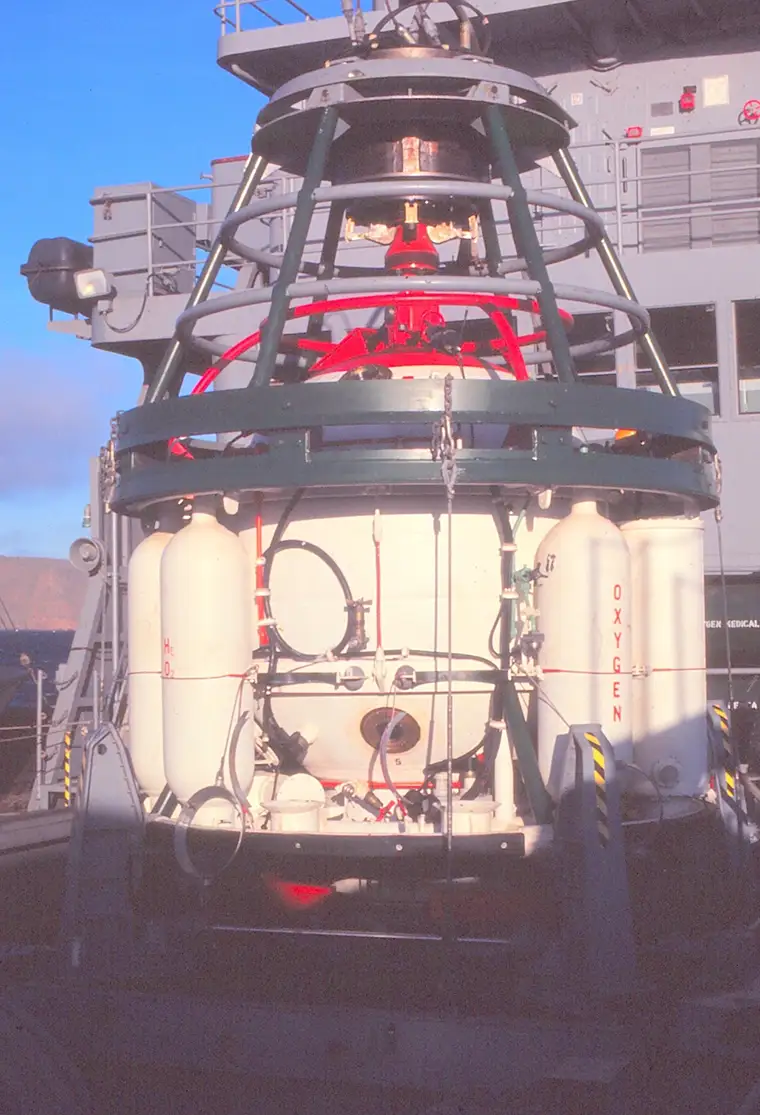

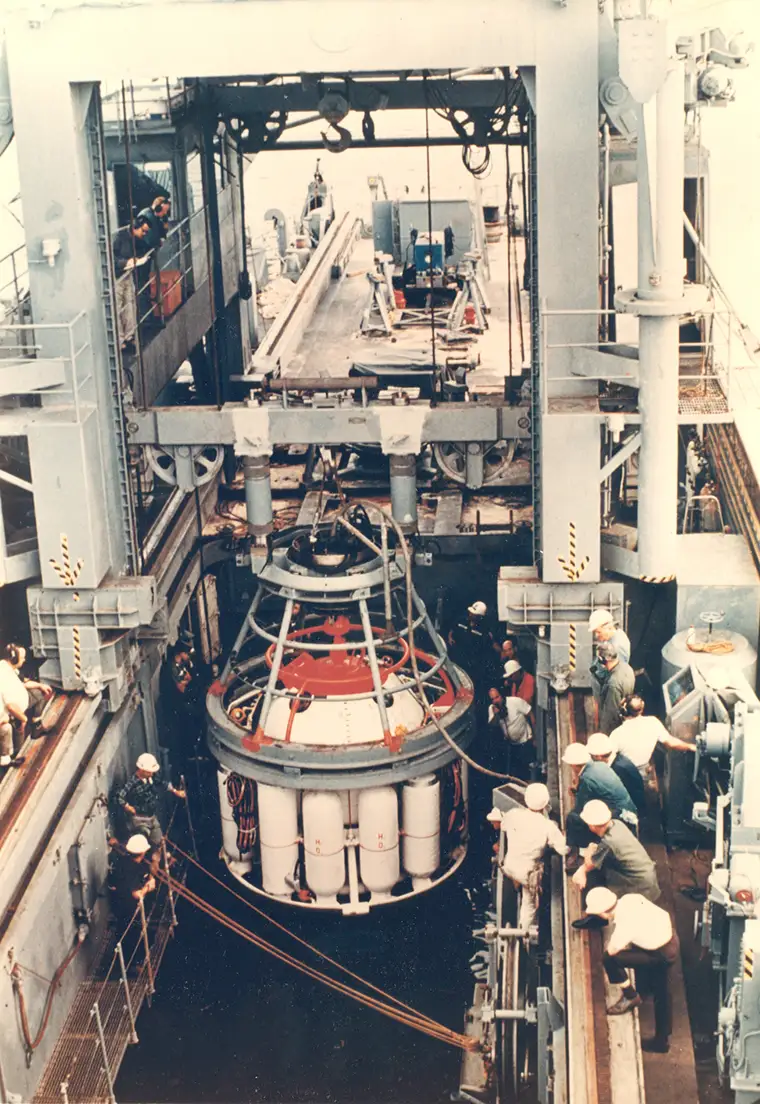

In November 1968, PTC-1 couldn’t be certified because of a “series of electrical grounds and battery and cable flood-outs.” A few days later, PTC-2 flooded on its only test dive to 180 m/590 ft. Cables, connectors, and all interior instruments and equipment were ruined. A patched-together PTC-2 was brought back into service, but the CO2 scrubber now blew cold heliox directly onto the divers because the deflectors were not replaced, thus increasing the effects of hypothermia. The electrical heater inside the PTC-2 did not work. The divers learned this as they prepared for the first dive on SEALAB III.

PTC-1 was found to have a bad seal and could not dock with the Deck Decompression Chamber-1 (DDC-1). It was useless.

On February 13, Aquanaut-NCEL engineer Dr. Larry Hallanger recalled a training dive on site off San Clemente Island using the Mk 2 Deep Diving System’s PTC, making the log entry: “Yesterday (February 12) was a PTC swim out and training dive with Eggar, McDole, Raymond, and Schmidt. We suited up about 0930 and then various problems delayed the dive until afternoon. Broke for lunch about 1130 and then returned to the DDC to await commencement of the dive. About 1330 we were pressurized and about 1430 actually entered the PTC. Depth was 11 m/35 ft and Larry Raymond and I made about a 5-minute swim. After locking back in we started an “unconscious diver” drill, where I was the “victim.” In raising us up, the latching fingers wouldn’t lock completely on the capsule pick-up mechanism.”

Aquanaut Fernando Lugo recalls that same training dive. Four divers were lowered to 35 ft to train on their Mk IX semi-closed dive rigs. Mk IX’s are Mk VIII’s modified to use from the PTC. With the training session completed, the Aquanauts returned to the PTC and closed and dogged the hatch, and the bell was hauled back up to the USS Elk River (IX-501). The method of securing the bell in the gantry utilized three latching dogs on a probe at the top of the bell. The electromechanical cable (EM cable) went slack once the load was taken by the gantry. However, only one dog was engaged. Recognizing the problem, the four divers were called out of the PTC, and Lugo and Van “Tinker” Bell were told to get in the bell and close and dog the hatch. They were to be lowered back to 35 ft, then recovered to re-engage and set the three dogs. Lugo and Bell had just closed and dogged the hatch when the one dog holding the PTC released and the bell dropped several feet in free fall. The EM cable went tight with a sudden jerk. The 2,500-pound lowering weight below the bell broke the wire to the downhaul winch and fell 610 ft to the seafloor. Lugo recalls getting slammed around inside. Only 12 unbroken strands remained out of approximately 100 in the contra-helically wound overbraid steel strength member, most having parted with the sudden stop. Lugo and the deck crew knew that, had the remaining 12 strands parted and the clump weight remained attached, the bell would have been dragged 610 ft to the seafloor with the two divers unrestrained inside.

The PTC was secured to the gantry with chains where she was. Lugo and Bell exited the PTC and headed for sickbay to be examined. Luckily, both men suffered only contusions. Repairs began. The EM cable termination was remade.

Navy Diver and Aquanaut Keith Moore, USN, recalls work being done to repair the PTC-2 Strength-Power-Communications cable at Mare Island shortly before the habitat was barged to Long Beach then to San Clemente. Junior Seabees were assisting, and the lead repairman was complaining of not being given enough time to do a proper job before transport to the experiment site. The late delivery meant a lack of testing and training. “The PTC was a disaster,” recalled Moore.

Moore recalls PTC-1 as not fully functional, so the five divers in DDC-1 couldn’t have transferred to the seafloor had Barth and Cannon opened the habitat anyway, except using PTC-2, leaving the first divers marooned on the seafloor.

Less than an hour after the PTC dropped, an electrical fire broke out on the gantry. Lugo was back on deck assisting with firefighting efforts, climbing the gantry, passing fire extinguishers to fire fighters. The fire, presumably electrical, might have been a result of the sudden jerk when the PTC dropped. It might also have been the fault of poor design and a lack of equipment testing. Lugo does not suspect sabotage.

On Thursday, February 13, in preparation for lowering the habitat, Hallanger made the log entry: “This evening starting about 1700. The habitat umbilical was removed from its reel and placed on a barge ready for lowering the SEALAB. This was necessary because the reel had no slip rings and the cable had to be plugged in prior to lowering. (Somebody goofed because this was first noticed as a problem last Sunday.)” The requirement for a reel stand with slip rings was known at the time the cable was ordered.

On February 15, as SEALAB III was ballasted to descend to the seafloor off San Clemente Island, it is reported, “At the pre-lowering inspection, several gas leaks had been observed when the habitat was submerged and the interior pressurized to 12 psi. The leaks were considered minor, and, according to on-scene Cmdr. J. M. Tomsky, not sufficient to warrant aborting the lowering.”

Perhaps Tomsky was distracted by other problems with the habitat. The operational depth was too deep for surface support divers. The Westinghouse submersible Deep Star 4000 was brought in for support observations. The NOSC SEALAB III “Sequence of Events” records on February 14, “First Deep Star Dive (#512) personnel reported that NORTH guideline had almost parted, and SOUTH guideline wire was fraying,” plus, “It appeared the habitat was not trimmed completely, heavy at the divers’ station end.” 2,495 kg/5,500 lb of lead pigs were removed from the divers’ station end, and 68 kg/150 lb placed at the observation room end.

If lowering was paused to trim the habitat, the prudent, competent decision would have been to also send divers in to seal the leaks from the interior when ambient pressure was low, the water was warm, and repair materials were easily available. At 610 ft, the leak rate would increase by 18.5 times due to the compression of the gas.

Project managers would have been well advised to perform a helium leak test in the dry dock when submerged tests were done in September 1968 at the San Francisco Bay Naval Shipyard. Such a test would have confirmed the capability for emergency decompression within the habitat as noted in the SEALAB III Operating Procedures. “The capability of the main cylinder of the habitat to be pressurized to 125 psi has been retained in the SEALAB III design.” Except the habitat was now planned for placement at 610 ft, requiring a minimum of 275 psi for emergency decompression. Had that emergency arose, no one inside the habitat would have survived.

On the surface off San Clemente Island, the habitat was leaking gas at 12 psi differential.

As described in the SEALAB III Operating Procedures, the “Heated Diving Suit System has been designed to provide supplemental heat to eliminate the motor loss and lowered mental capability normally associated with diving in cold water.” However, a few days before the first dive to open the habitat on the seafloor, the electrically-warmed wetsuits were pulled from service for electrical shorts.

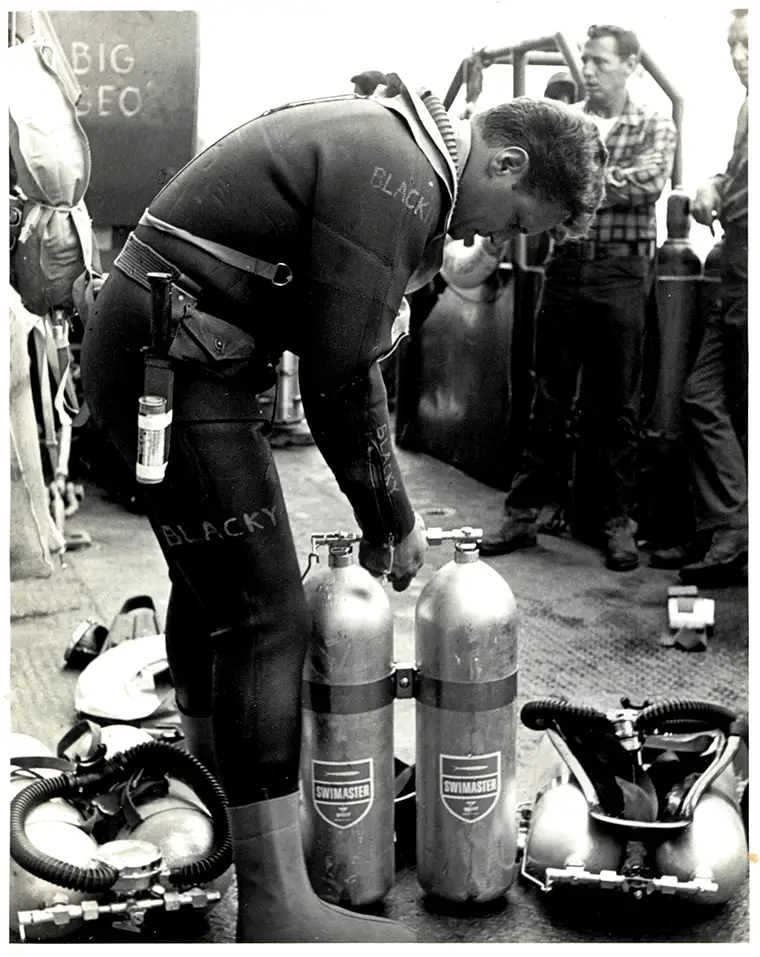

There was no hot water for the hot water suits. There were no dry suits. On the two dives to open the habitat, Aquanaut Dick “Blackie” Blackburn wore a custom-made 3/8” neoprene wetsuit he ordered from Voit. The other three divers wore miscellaneous wetsuits or hot-water suits.

There was a lack of testing and in-water training of the Mk VIII and Mk IX semi-closed rebreathers at depth.

- In-water training dives were to a maximum of 21 m/70 ft.

- Heavy umbilicals sank and became easily entangled.

- Breathing resistance was very high due to an untested hose modification intended to prevent the inhalation bag from collapsing.

- The Aquanauts had to continuously press the system bypass to get gas. Anoxia was a major concern.

“Testimony from SEALAB participants indicated the Mk IX had not been previously used in training dives deeper than 18 m/60 ft and late modifications, designed to prevent breathing gas cutoff, were not tested at EDU (USN Experimental Diving Unit) to ascertain any breathing restrictions they might cause under heavy work.” (Ocean Industry, May 1969)

Aquanaut Richard “Blackie” Blackburn explained, “Semi-closed and closed-circuit breathing systems require the lungs to do all the work of recirculating the gas through the Apparatus and CO2 absorbent. There is a small flow of fresh gas being metered into the inhalation breathing bag. The least amount of breathing resistance in or out will have a devastating effect on the diver.”

Following the first dive to 610 ft, Blackburn wrote a note and sent it topside with the Mk IX’s to P.A., “because Berry and Bob had such a hard time breathing and both had mental problems after their first dive.” Blackburn identified a problem with the Mk IX breathing rig in an after-dive report, writing a caution for P.A. during dive rig preparations for Dive 2: “Check that buddy breather slide valve is on when rigs are sent down. Because the second stage + hose between the slide valve and second stage will be squeezed if not left on. I think there is a great restriction in the inhalation hose because of the stiffener in between the two bag fittings. Take a look, that is a small hole to have to suck through at 600 ft.”

Cmdr M. Scott Carpenter was assigned as “Deputy On-Scene Commander” and “Special Assistant for Aquanaut Operations” and acted as the Navy’s “Senior Aquanaut” due to his rank. He was tasked with, among other duties, “the administration of the SEALAB III experiment, and as advisor for Aquanaut safety, operations, and equipment.” Carpenter might have leveraged those positions more effectively to serve as ombudsman for the divers.

Problems Are Seen Early

With SEALAB III on the bottom, helium leaks increased to 3,000 ft2/hour. A half-million cubic feet are lost before salvage dives begin. The amount of gas leaking out was a little more than 2.5 ft3/minute at 610 ft, consistent with filmed images of the leaks. The gas expanded 18.5 times on the way to the surface.

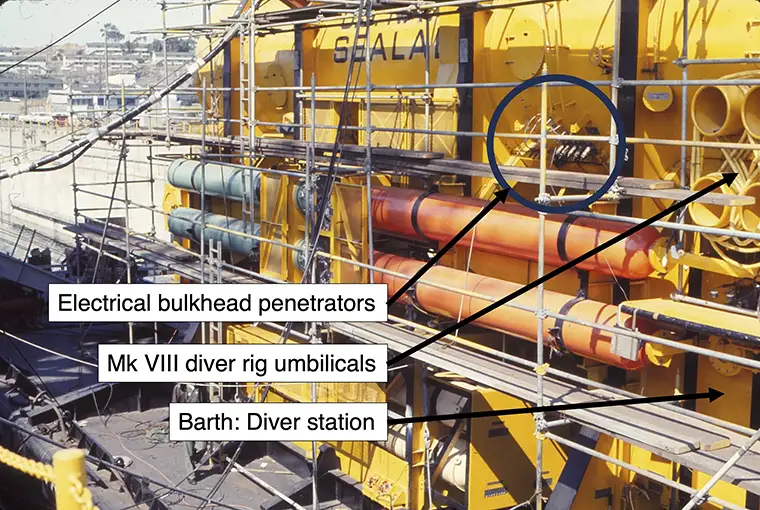

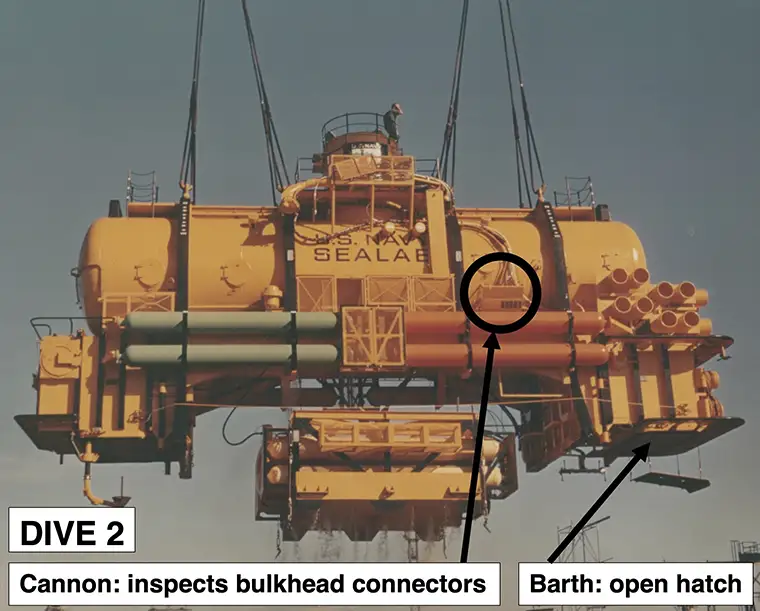

At 610 ft, SEALAB III was beyond the range of surface support divers. Robotic Remotely Operated Vehicles (ROV) were not common. The Westinghouse manned submersible, Deepstar 4000, was brought on site to carry observers to the habitat in a pressure-proof hull. “Leaks are seen from the Deepstar 4000 after the habitat is on the bottom. Cmdr. Scott Carpenter, who was the observer on the Deepstar 4000, reported seeing seven streams of gas apparently coming from cable penetrators.” (Ocean Industry, May 1969)

The rate was unsustainable, and would have doomed the mission if repairs couldn’t be made in a short amount of time.

Instrument cable jackets were seen rupturing at the surface due to expanding helium gas that had leaked through habitat penetrators and into the cables.

“Gas loss was further increased by gas hosing up through the main electrical cable, causing the sheathing to burst in several places.” (Ocean Industry)

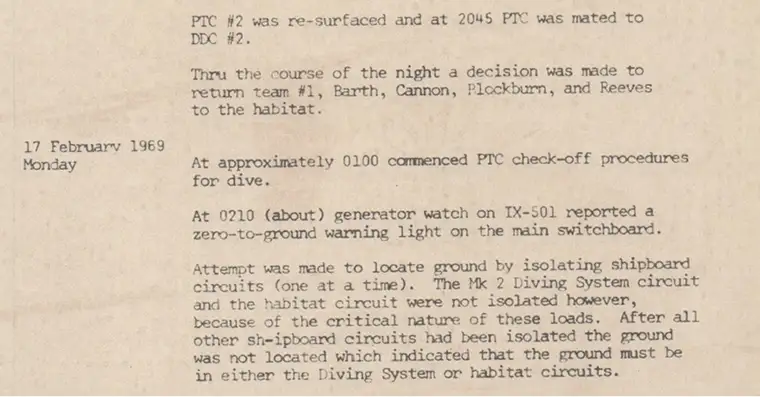

Power surges and ground-fault alarms on the main power cable to the habitat (440VAC, 3φ, 152kVA) confirmed main electrical cable jacket failures causing shorts to seawater.

The Two Dives

Team 1’s nine men were divided into sub-groups of four and five. The four-man group consisted of Warrant Officer Bob Barth, civilian electronics engineer Berry Cannon, Aviation Ordnanceman First Class Dick “Blackie” Blackburn, and Photographer’s Mate First Class John F. Reaves. They were assigned to DDC-2 and pressurized to an operational depth of 610 ft at a rapid rate of four hours instead of fifteen hours, pushing the edge of High-Pressure Neurological Syndrome (HPNS), one of the significant limitations of deep sea diving.

The five-man team—Engineman First Class Richard C. Bird, civilian research engineer Richard A. Cooper, civilian research physicist George B. Dowling, Machinist’s Mate Second Class Jay W. Myers, and Medical Corps Lt Cmdr James Vorosmarti, Jr., MD—were assigned to DDC-1 for the fifteen-hour compression. They were to join the four-man team after they had opened the habitat.

Dive 1

The four divers entered PTC-2 for its first trip to the seafloor since its repair following the flooding incident. The descent to the habitat took two hours, considerably longer than the 30 minutes the team anticipated. The wind chill of the unbaffled fan created further heat loss in the divers.

The divers had to wear a standard skin diving face mask and use a bite-type mouthpiece because the commercial clamshell full facemask and Navy-designed facemask did not provide a satisfactory seal when used with the positive-pressure Mk IX system.

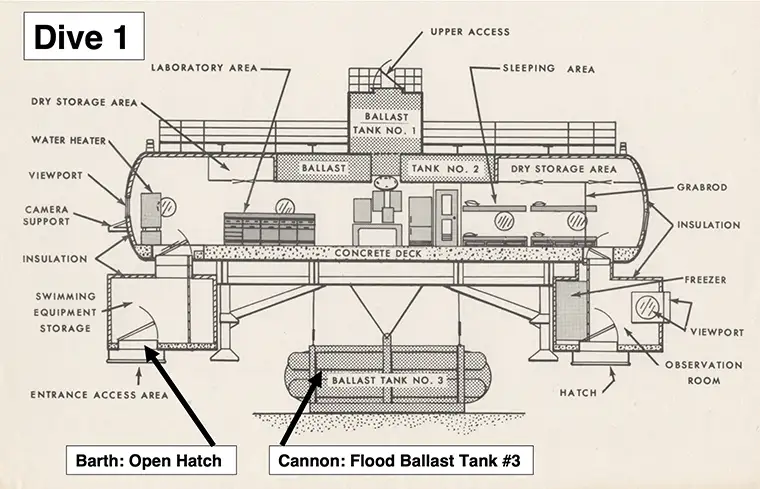

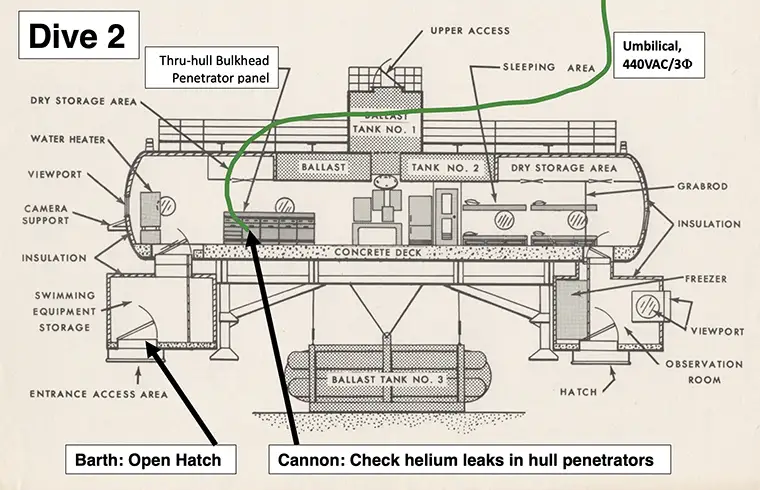

In the station on the bottom, Barth and Cannon opened the PTC hatch and hauled in their umbilicals. They connected them to their Mk IX breathing rigs kept inside the PTC. They exited the PTC and headed for the habitat to make repairs.

Cannon completed his tasks of flooding Ballast Tank 3 and releasing the hydraulic system pressure to the leveling cable clamps—thereby securing the habitat in its level position—then headed back to the PTC. He was out for 13 minutes. He told Blackburn when he returned, “Cold. Very Cold.” His teeth were chattering. He was reported to have a dazed look, and was breathing extremely hard.

Barth was fighting to open a 1.2 m/4 ft square hatch inward against an interior pressure of +4 psi. While the dead weight of the hatch was 68 kg/150 lb, the positive interior pressure created 4.2 tonnes/4.6 tons of force holding it shut. Topside had a TV camera looking at a differential pressure gauge and knew the interior pressure was too high, but failed to equalize the pressure.

The SEALAB III Operating Procedures describe “equalizing lines extending from each of the lower rooms to their respective skirt… The atmosphere inside the habitat is thereby equalized with the surrounding sea pressure, and the interface between the habitat atmosphere and the sea water is established at the bottom of the skirts. This provides a safety volume below each hatch, necessary for expected fluctuations in the water level due to tidal variations and changes in internal volume. The Aquanauts then swim into the skirt area, open the 122 cm/48 inch square hatch, and climb a ladder into the room.” It said a second time, “Prior to entering the SEALAB III habitat, Aquanauts from the transfer capsule open a valve to an equalizing line extending from each room to its respective skirt. The slight over-pressure inside the habitat blows the water from the skirts.” In reality, the input gas supply to the main habitat exceeded the amount that could be effectively exhausted through the equalization valve into the skirt. Without any means to communicate between Barth and topside, Barth has no way to know the true interior overpressure.

Navy Diver Keith Moore, USN, worked in the “gas shack” on USS Elk River (IX-501) during PTC-2’s two dives to the seafloor, along with USN Diver Mike Ruden. He had his hand on the valve that controlled the air flow into the habitat while it was on the seafloor. He understood the problem of the habitat interior pressure being over ambient, creating a positive pressure holding the entry hatch shut, the same understanding that Bond and Mazzone were trying to convey to Tomsky in the control van. Moore recalls dive #1 habitat interior pressure was +4 psi differential. On Dive #2, the interior pressure was bumped up to +6 psi.

Moore asked Tomsky three times during Dive #1 to allow him to lower the interior pressure in the habitat to allow Barth to open the entry hatch by partially closing the valve to lower the air flow into the habitat. The helium leaks in the habitat would have bled pressure down reasonably soon, and Barth could open the hatch and gain entry. Moore recalls being directed all three times by Tomsky to “hold pressure.”

There were no comms between the divers and the PTC, so communication with topside was impossible.

Barth swam back to the PTC and described his condition as “dizzy, weak, about to pass out and in need of assistance.” His dive lasted under 15 minutes. The four divers reported they had never been so cold.

Hypothermia plagued divers in the PTC, leaving them shaking uncontrollably, teeth chattering. Their faces were so cold they had difficulty speaking.

No progress was made on opening the hatch or sealing the leaks.

PTC-2 is returned to the USS Elk River and the men transfer back into DDC-2 to rest and warm up.

Electrical Grounds

It is reported to the on-site commander that the main power cable is showing shorts to seawater.

Inside the habitat, “All electric circuits are ungrounded to eliminate shock hazards. However, since an accidental ground in the system could create a shock hazard, the cases of all portable electric equipment must be grounded to the hull. Wherever equipment is to be plugged into a receptacle, the grounding is best accomplished by using a three-conductor cable between the plug and the equipment. One of the conductors must connect the grounding pin to the frame or case of the equipment.” (SEALAB III Operating Procedures)

Thus, it is shown, the hull was the electrical ground.

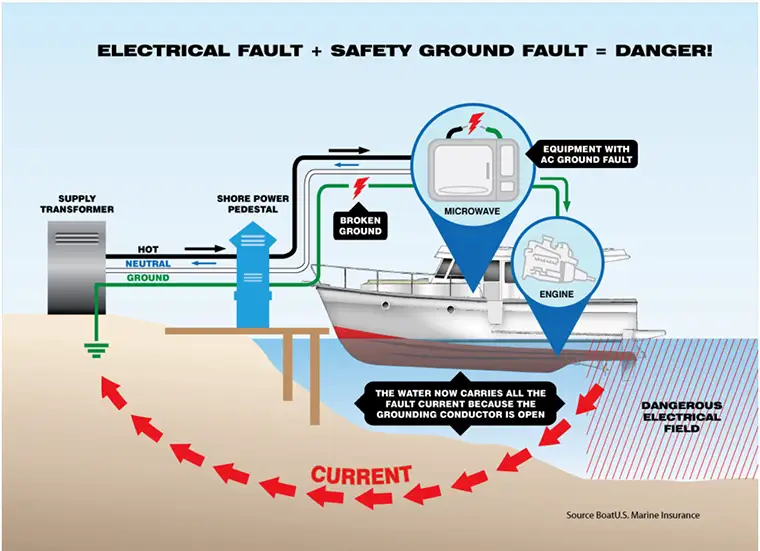

Electric Shock Drowning (ESD)

With Electric Shock Drowning (ESD), there is no way to tell if water is energized with fatal levels of electricity.

An ESD victim’s muscles become paralyzed by the electrical current, they are unable to swim, and ultimately they drown. In the vast majority of ESD cases, the victim’s autopsy shows no signs of electrical injury.

Because of the increased conductivity of seawater, ESD is less common in the ocean. Normally, the higher voltage and current with lower resistance would pop breakers first. However, the SEALAB habitat had no breakers on its main power cable—only ground fault alarms that were going off.

Dive 2

Only four hours after returning to the DDC and one hour of sleep, Team 1 was asked to dive again. Barth put on a blue jumper under his hot water suit before the dive to help with insulation, plus a neoprene hood, gloves, and booties. Cannon wore a hot water suit without under insulation, no gloves, and no hood. Hot water suits were baggy to allow hot water to circulate. Bottom water temperature was 8.3 °C/47° F.

Just prior to the second dive, “the flood gauge in the habitat sounded the alarm: Water had reached a depth of 6 in/15 cm due to a slight negative differential pressure (DP) presently being maintained within the habitat.”

The hatch had opened itself.

Without the habitat legs deployed, flooding on one end would make that end of the floating habitat heavy, and it would begin to sink lower than the other. This would unevenly strain the wire ropes, previously secured on Dive 1, tying the habitat to the ballast frame. If the wire ropes broke, the habitat would float uncontrollably to the surface. With a concrete deck and upper ballast tanks 1 and 2 flooded, at some point she would roll on her side. If the entry hatch was not secured, water would flood the interior. Most likely, she’d float with the observation room end up. Any divers on the inside would have died of air embolism.

Before Dive 2, Tomsky was torn: open the hatch, or keep the hatch closed? He directed the interior pressure to be bumped back up to a +6 psi differential pressure to provide a positive sealing force on the hatch. This also precluded Barth from opening the hatch the second time, as it created nearly 7 tons of force holding the hatch shut.

On the bottom, a jerry-rigged hot water system for the divers’ suits failed to work. Barth and Cannon were greatly disappointed but decided to dive anyway.

On dive 2, Barth requested that the other two divers (Blackburn and Reaves) go out, as he and Cannon were still quite cold. This request was denied by Tomsky.

Barth worked again to open the hatch against positive interior pressure. He was unaware he was working against 6.9 tons of force holding the hatch closed.

Cannon was assigned to check helium leaks and umbilical connections.

Barth was underneath the diver station working to open the hatch while Berry went to check on the helium leaks from the penetrators.

We know the pieces. Some conjecture ties them together.

As seen in Figure 12, Berry’s direct view of the metal shell penetrators was blocked by the protective cover plate. It was further obscured by a curtain of helium bubbles. There was no direct illumination by exterior lights. He worked in the shadows. He had to bring himself in close to view the leaks. Contact with the habitat was unavoidable. He was without a neoprene hood and gloves needed for both thermal and electrical insulation. He was dangerously cold, physically exhausted, and mentally fatigued. Grabbing the habitat, he was now grounded and became part of the electrical path. The hot side was lurking.

In this moment, he might have grabbed a metal shell connector body to see if squeezing it would tell him about the pressure behind the leak. He may have pulled on a cable. There was one cable water block towards the habitat interior and two upstream towards the main umbilical. The cable jacket may have split from helium leakage from the habitat, while the metal shell connector may have shorted power to the body.

In the PTC, both Blackburn and Reaves reported that they heard a scream through the water.

Like a lightning bolt, a burst of high-power electricity ripped through Cannon’s body. Every muscle violently contracted. He spit out the regulator and his arms contracted, striking his face and knocking off his face mask. He collapsed, slid over the high-pressure gas tanks, and sank towards the seafloor.

Cannon’s body settled a few feet from Barth, who quickly diverted to help his buddy.

Wearing neoprene gloves, Barth was not grounded to the habitat and avoided electrocution himself.

Though convulsing, Cannon was already dead. His teeth were clenched so tightly that Barth, and then Blackburn, couldn’t get the regulator mouthpiece into his mouth.

The dive lasted seven minutes.

Blackburn was already outside the PTC when Barth made it back, exhausted. Blackburn and Reaves helped Barth into the PTC. Barth said that if the PTC had been 6 m/20 ft further, he would not have made it. Blackburn then recovered Cannon and brought him to the PTC where he was lifted up into the PTC.

In the urgency to get Cannon back to the surface where medical doctors were onboard, Barth, Cannon, and Blackburn’s Mk IX rigs were left outside the PTC. Both Blackburn and Moore recall the three dive rigs returned to the surface on the exterior of the PTC, dangling 100 ft below the bell.

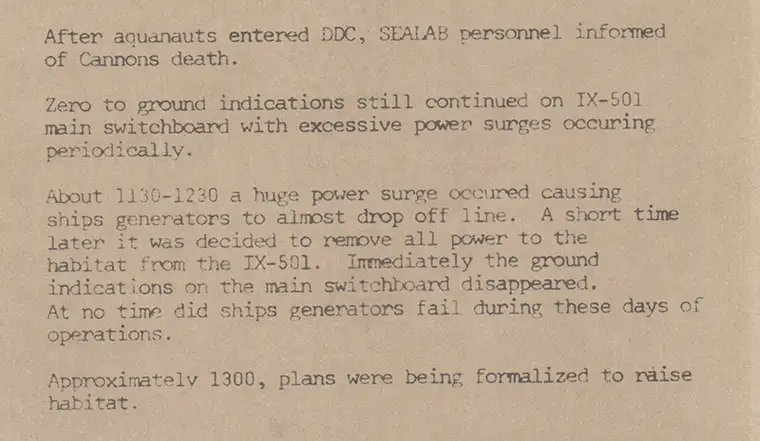

Because PTC-1 was damaged, Lt Cmdr James Vorosmarti, Team 1 medical doctor in DDC-1, could not be transferred to DDC-2 to meet the Aquanauts ascending from Dive #2. It didn’t matter. Cannon was pronounced dead on the way to the surface.

Hallanger’s log states that Captain William M. Nicholson, SEALAB III Project Manager, directs Cmdr Jack M. Tomsky, on-scene Commander, to get another dive team ready. That did not happen.

Aquanaut Blackburn recalls, “If we had adhered to normal, accepted, and approved diving practices, the first dive probably would not have been made, let alone the second one. There is always to be communication with the divers. In our case, there was no communication with the divers outside the bell: not to the bell, nor to topside where it was imperative to coordinate the opening of the hatch with the reduction of pressure in the Lab which was monitored topside through a closed-circuit TV camera system.

This CCTV system had a clear view from the control van and the main diving console on the support IX-501 showing both the diver in the water on the bottom under the hatch and the Differential Pressure Gauge (DPG) in the Lab. The pressure was never reduced on either dive 1 or 2, thus there was no way a human could have opened the hatch. Then there was the additional problem of the power umbilical (440 volts) from the support ship IX-501 shorting out against the hull of the Lab.”

Power To The Habitat Is Cut

A few hours after Cannon’s death, as plans were made to raise the habitat, a huge power surge in the habitat almost knocked the generators of the IX-501 Elk River off line. Power was cut to the habitat, and the ground fault alarms fell silent.

The Empty Canister

Other explanations for an empty canister were offered to the BOI, but dismissed.

When Barth, Blackburn, and Cannon’s Mk IX units returned to the surface on the outside of the PTC rather than inside it—as they normally would have on an uneventful dive—the units could have free-flowed on ascent. Baralyme residue was found in the rebreather exhaust path of the rig with the empty canister, indicating it had been flushed out.

Aquanaut Lt. Cmdr Martin Harrell, SEALAB III, Team 5, recalls his “own experience that caused the carbon dioxide absorbent canister of my Mk XIII SCR to empty its baralyme into the sea during a training dive. This confirms an alternate explanation for how the CO2 canister of a Mk IX SCR could have been emptied.”

It was also Standard Operating Procedure (SOP) to empty canisters of wet baralyme to keep the chemical from corroding the interior components of the rebreather, though this was not a SOP situation.

In addition, it was never established that the rig with the empty baralyme canister was Cannon’s.

Aquanaut Moore recalls helping P.A. Wells load the Mk IX dive rigs after Dive 1. The rigs were to be used on Dive 2. He recalled the dive locker was mayhem, but he and P.A. were focused. Moore called P.A. Wells “my mentor.” Moore recalls the use of a strap wrench needed to open and close the dive rigs’ baralyme canister. Moore carried the refurbished rigs to PTC-2 to be loaded in for Dive 2. He was certain he would have noticed if one was empty of baralyme due to the difference in weight. He absolutely believed none were light. He described the Aquanaut checkout procedure before a dive, and believed any empty rig would have been found in their pre-dive checkout, too.

Aquanaut Andy Pruna, Team 5, said, “P.A. was the most capable guy, the most meticulous. I’d dive a rig he prepared any day.” A dozen other identical quotes from his fellow divers could be appended here.

Following Cannon’s death, Hallanger wrote: “I have been assigned to assist Marty Harrell in investigating the umbilical and habitat for damage. The main power cable has dead shorts on two legs and a higher resistance short on the third. Thus, even if we had fixed the gas leaks we probably would have had to abort anyway.”

Oxygen toxicity was unlikely as the heliox gas was premixed and all divers breathed from the same source.

Fernando Lugo said that pressing the bypass, which the deep divers had to do often with the untested system, provided premixed gas from prefilled tanks. The semi-closed system would have exhausted the CO2. The chance of carbon dioxide poisoning was thereby further reduced.

Responsibility

There are far more problems with SEALAB III than this column has space to list—serious problems in which P.A. Wells had no involvement, responsibility, or authority to address.

In hindsight, it is ridiculous to think that one man not filling one canister could have imploded the entire US Navy’s Man-in-the-Sea program.

Bond stressed, “The Principal Investigator decides where to draw the line between acceptable risk and excessive hazard; the responsibility for the decision belongs to that person alone.”

Responsibility for the failure of the SEALAB III experimental habitat rests with Captain William M. Nicholson, SEALAB III Project Manager.

A post-accident interview with Nicholson, published March 17, 1969 by the National Observer, details his disconnect from the reality the Aquanauts faced on the seafloor, referring to the fatal dive as “a simple process,” and “a perfect example of Murphy’s Law.” He added that “the mishap could have happened at 60 ft as easily as 600 ft,” and that the danger of hypothermia was no worse than “gulping frigid air while skiing.”

Nicholson was advised by Northrup Corporation’s Nortronics Division as Systems Engineering Support Contractor for the USN’s Deep Submergence Systems Project. Nortronics was paid to perform a number of activities in support of SEALAB III including monitoring of the design, development, and fabrication of the SEALAB system to identify potential problems and recommend solutions; Man-in-the-Sea program evaluation and analysis for Navy Management; preparation of interface control drawings for the SEALAB system and deep diving system; preparation of test plans and policy documents, technical review of test procedures; development of a scenario for preoperative testing; preparing safety certification plans for Aquanaut equipment; and related technical support. (SEALAB III Press Handbook)

If Northrup provided good and timely advice, it was largely ignored.

George Bond said afterwards, “Perhaps I am biased, but I believe that topside bureaucrats should be qualified divers, just as firmly as I believe that proofreaders should complete at least three grades of elementary education.”

SEALAB III, Team 1 Aquanaut Dick Bird believed “Chief Wells was kicked under the bus,” and hoped, “one day someone will stand at a podium and the real story will be told.”

Within the files that have resurfaced is an LA Times article by Susan Stocking, published March 23, 1969, titled “SEALAB Tragedy: Despite Navy Inquiry, a Host of Questions.” Numerous specific problems were identified at the BOI, with no clear answers as to “Why?” She asked then, only a month after the habitat was raised, “And if the decisions to make the deadly repair run were made precipitously, who was to blame—the divers, or the commanders aboard the SEALAB’s surface support ship?”

It is reasonable to conclude that P.A. Wells had no culpability in the abrupt end of SEALAB III.

The first manned moon landing was just four months away, and these young and daring Navy saturation divers were swept up in the enthusiasm of their own quest to step on unknown worlds. Lt. Cmdr James Osborn, Team 3, Team Engineer, thoughtfully reflected on those days some years later: “As an aside, I’m convinced that if the habitat had been opened and dives conducted, there would have been deaths. Our training on the habitat itself was minimal, and I was supposed to be the Team Engineer! The cold and the lack of adequate protection, I’m convinced, would have killed people if nothing else!”

Conclusions

There is greater evidence that Berry Cannon died from electrocution than CO2 poisoning.

Paul “P.A.” Wells should be formally exonerated, now posthumously, by the United States Navy, if only to clear its own name, and restore honor to both.

Epilogue

Simultaneous with SEALAB III, other branches of the USN were working with NASA, the US Department of the Interior, and other pathfinders on the Tektite manned habitat program in Great Lameshur Bay, USVI. The Tektite missions were well thought out and all successful. (Journal of Diving History issues 91, 92, 93, and 106)

With multiple books published on the subject, including by participants no less senior than John Craven, and more than a half-century since the events of February 17, 1969, the statute of limitations has certainly passed. The surviving Aquanauts, like World War II’s Easy Company, this “Band of Brothers” should be free to tell their story.

Aquanaut John Kleckner writes, “After SEALAB III was discontinued, I spent several years on the IX-501 and the Mk2 DDS (PTC/DDC) doing a lot of modifications and testing of the system. During this OPEVAL/TECHEVAL there were a lot of corrective measures taken to eventually get the system certified.”

Following SEALAB III, the US Navy regrouped and considered the applications of saturation diving in covert operations from mobile platforms. It was carried forward with astounding results, in particular the clandestine projects known as “Operation Ivy Bells” in the Sea of Okhotsk, USSR, 1970s-1981.

In October 1971, the Deputy Chief of Naval Material, Thomas Davies, signed the order for the disposal of the SEALAB III habitat. “Final disposal instructions shall prohibit its use as a pressure vessel or display.” Like a scene in Les Misérables, it was stripped of any usable parts, then flame cut into scrap. The opportunity to do a forensic study of the habitat in detail—including O-rings, electrical insulation of connectors, resistance to positive interior pressure, electrically driven corrosion, and more—was lost.

After SEALAB II (1965), an after-action report was compiled and published to document what went right and what needed to be improved. In 1925, the loss of the submarine S-51 provided the USN an opportunity to learn from the tragic loss of 33 men. It produced a 100-plus page report, including fold-out schematics, that delved into submarine design, recommended procedures for surface running during night operations, and salvage techniques developed to raise the boat. Without an open, honest, and factual review of SEALAB III, the USN missed the golden opportunity to learn from both the mistakes and the successes of that specific manned habitat project.

If the USN felt that there was nothing more to learn, SEALAB III should have been canceled by DSSP in December 1968 as it was in obvious trouble.

Losing a diver of such talent, dedication, and skill as Berry Cannon was an immeasurable loss to the USN in itself. Berry was SEALAB II, Team 1, and SEALAB III, Team 1 for a reason. He was first-in-class of a new kind of Navy Diver: Electronics Engineer and tough-as-nails Sat Diver. His death was from friendly fire.

That full blame for the fatality was laid on one enlisted man rather than a flawed command structure is another troubling outcome to be addressed. SEALAB III is a story of command in over its head, unguided by Honor-Courage-Commitment.

The Aquanauts’ silence was never meant to indicate their acquiescence to the BOI conclusions. They have been denied the freedom to tell their story. They have carried that burden their whole lives.

The USN has many things in its storied history to be immensely proud of, and the discovery of the principles of saturation are certainly one. It would be seen as a show of strength and honor to exonerate Paul “P.A.” Wells.

In 1991, one of the distinctive explosively-formed habitat end bells was discovered in a San Francisco scrap yard by SEALAB II Aquanaut Bob Sheats. Sheats brought that to the attention of Ron Roehmholdt, Exhibits Manager at the Naval Undersea Museum in Keyport, Washington. In 2001, Ron’s passionate commitment resulted in proudly placing that last remaining piece of the SEALAB II/III habitat on permanent display. A few years later, San Diego master model builder, Jerome McAuliffe, built and donated an Aurora model of SEALAB III to give context to the end bell display. SEALAB will never be forgotten.

The USN SEALAB Aquanauts, all of them, will forever remain towering giants of history whenever stories of man’s advance into the vast depths of the sea are told. They are the pioneers of Saturation Diving and hyperbaric medicine. Every generation needs examples such as these men to live up to.

Be a Part of Diving History!

The Historical Diving Society USA is a non-profit organization dedicated to serving the dive community by:

• Researching, archiving and promoting great moments in dive history.

• Honoring the contributions of underwater pioneers.

• Facilitating access to the rich history of diving on various platforms.

• Enhancing awareness of and appreciation for underwater exploration.

To access our treasure trove of dive history and become a member, visit us at: www.HDS.org. We are also on Facebook: Historical Diving Society USA

Acknowledgements

SEALAB II and III Aquanaut Bill Bunton first challenged the USN BOI conclusions in his book, Death of An Aquanaut. He was on the right trail. Sincere thanks to Mary Lou Cannon for sharing Berry’s archives and for bravely permitting the re-examination of her husband’s death at 610 ft.

It’s easy to see why Berry fell for this lady. Aquanaut Dick Bird poetically referred to the Aquanaut’s wives as “The Women behind the Men-in-the-Sea.”The authors are deeply indebted to Aquanauts Bob Barth, Dick Bird, Richard Blackburn, Larry Bussey, Leo Gies, Larry Hallanger, Martin Harrell, John Kleckner, Fernando Lugo, Keith Moore, Jay Myers, Jim Osborn, Andy Pruna, and Larry Raymond for their encouragement, hints, contributions, and review. Their achievements are legendary. There are few of their caliber.

The authors express their gratitude to those who were kind enough to share their memories, knowledge, and primary source materials in their possession. Greatest thanks to Mary Ann Martin Hallanger for sharing Dr. Larry Hallanger’s archives. Dick Long, Diving Unlimited International, shared his expertise in wet suits and hot water suits from SEALAB II and other means of thermal protection necessary at great depth. Robert Wernli, with a profound sense of history, saved the files of Howard Talkington, Head, Ocean Technology Branch, NOSC-San Diego that included the SEALAB III Sequence of Events relating to the heroic, yet futile, attempts by Barth and Cannon to open the SEALAB III habitat. Talkington’s log contained the key insight, the electrical ground faults, which brought this story to light.

DIVE DEEPER

InDEPTH: Sealab lll: Another Letter to the Editor

InDEPTH: Letter to the Editor: Regarding Sealab lll

InDEPTH: Remembering Sealab I by Ben Hellswarth

Periscope Films: Sealab III Underwater Habitat Leaves San Francisco Bay October, 1968 (Raw Footage) 33794

US Navy: SeaLab III Command Information Bureau— 100 fathoms deep: SeaLab III by White, Robert H.

Defense technical Information Center: NEDU Report 9-10. Saturation Dives with Excursions, For the development of A decompression Schedule for Use During Sealab III by J.K. Summitt, LCDR, MC, USN NEDU

InDEPTH: Enabling a Permanent Human Presence Under the Oceans from 2027

Kevin Hardy was inspired in his youth by the U.S. Navy’s Project Nekton (bathyscaphe Trieste), and its Man-in-the-Sea program (Project SEALAB). A lifelong fascination began. In 2011, following a career that spanned 40 years in ocean engineering at the Scripps Institution of Oceanography/UCSD, Hardy was personally recruited by James Cameron to join his DEEPSEA CHALLENGE Expedition, with a goal to build two unmanned landers capable of reaching the deepest ocean depths. Following the Cameron adventure, Hardy founded Global Ocean Design LLC to develop undersea vehicle components and systems. He holds fundamental patents in the field. He was awarded a Doctor of Science (honoris causa) from Shanghai Ocean University in 2018, the first honorary degree awarded since their founding 116-years prior.

Since 2015, Hardy and Ian Koblick cover manned undersea habitats for the Journal of Diving History. Hardy also writes a column, “Lander Lab”, for the Marine Technology Reporter.

References

References include: “Press Handbook, SEALAB III Experiment, The U.S. Navy’s Man-in-the-Sea Program (September 1968),” and “SEALAB III Habitat Operating Procedures (October 1968).” This article also benefited from Capt George Bond’s text, “Papa Topside: The SEALAB Chronicles of Capt. George F. Bond”, Bob Barth’s “Sea Dwellers: The Humor, Drama and Tragedy of the U.S. Navy’s SEALAB Program,” Miller and Koblick’s “Living and Working in the Sea,” and Ben Hellwarth’s “SEALAB: America’s Forgotten Quest to Live and Work on the Ocean Floor.”