Community

Mission 2020: The Dive Industry’s Challenge to Eliminate Single-use Plastics

If you’ve been active in the dive industry over the last two years, and/or bought any of Fourth Element’s uber-divewear, you’ve no doubt heard of Mission 2020. Now quick, answer me this: What the heck is Mission 2020? Who’s behind it? What are they hoping to achieve? Ha! Thought so! Yes, it has something to do with conservation. Here InDepth editor Amanda White sits down with hyperbaric pied piper Fourth Element founder Paul Strike to get the deets. Hint: It’s all about the plastic, and the entire dive industry (well almost) has gotten involved.

By Amanda White

“Be the change that you wish to see in the world.”

― Mahatma Gandhi

Almost two years after the announcement of the Mission 2020 Pledge, nearly 200 dive industry organizations and businesses have pledged to do their part to reduce their company’s impact on aquatic environments.

For those of you who haven’t heard of it, Mission 2020 is a collection of pledges from organizations in the diving industry to change their business practices in order to help protect and preserve our oceans for the future. The primary focus of the pledge is to reduce or eliminate single-use plastic before World Oceans Day in 2020. Plastic is an issue that is at the forefront of a lot of consumers minds. Scientists from the nonprofit advocacy group “5 Gyres” found there are 5.25 trillion pieces of plastic debris in the ocean. Of that, 269,000 tons float on the surface, while almost four billion plastic microfibers per square kilometer litter the deep sea.

Mission 2020 was founded by UK-based dive garment company, Fourth Element in hopes of combating their contribution to the growing plastic problem. We caught up with 4E co-founder Paul Strike who is in charge of product development to see what the state of Mission 2020 is now.

How did Mission 2020 come about?

Paul Strike:

Jim [Standing] and I had a number of conversations at the 2017 DEMA tradeshow about doing something for the environment. A couple of months later we were discussing it [Mission 2020] again and came up with an idea: Wouldn’t it be amazing if we could actually encourage other people, other companies, to join us and do something that would make a difference? That’s how Mission 2020, as the industry knows it, was born. It’s not about Fourth Element, but about developing an industry initiative that will allow all of us to speak with one voice.

So it would have more power than just a single company behind it?

Yes, that kind of combined effect of having a number of companies: actually, in fact, a whole range of people and businesses and brands, dive centers, and organizations involved in the scuba diving industry, all coming together with one common cause– to do something positive for the ocean. There are nearly 200 entities that have made a pledge to effect change under that Mission 2020 heading. We are an industry that enjoys the ocean and makes a living off of it, so it’s in our best interest not to screw up our playground.

A strong and powerful message is being presented by the diving industry through Mission 2020. It could be the only and is certainly the first industry in the world to take some kind of combined, unified stance on this, one that is sending a strong message to consumers and other businesses.

Why did Fourth Element choose to focus on single-use plastics?

Well, think about how much plastic is involved in packaging a pair of scuba fins. And that’s a big, relatively heavy-duty plastic bag with a plastic carry handle that sometimes clips together. And I suppose it would be interesting to find out how many pairs of fins are sold in scuba diving. You know, that’s probably hundreds of thousands, isn’t it? And that’s just one product! It’s scary. That is just a huge amount of plastic. The magnitude of these plastic stats and of what’s going on globally is just… It’s mind-boggling. It’s so huge, the impact, it’s almost a bit like when people are talking about distant planets; it’s very difficult to get your head around it because it’s too big.

Thankfully, it’s something that so many people are talking about and obviously not just in the dive industry. You can’t seem to turn on the TV without there being something about plastic. Thankfully, there are lots and lots of companies changing things. But equally scarily, there are lots of companies that don’t seem to be making any changes.

What are you changing in order to reach your Mission 2020 goals?

Jim and I are both equally committed to trying to achieve these goals. The whole company is behind this mission. From the people designing and creating the clothing to those packing and dispatching it everyone in the company is behind this.

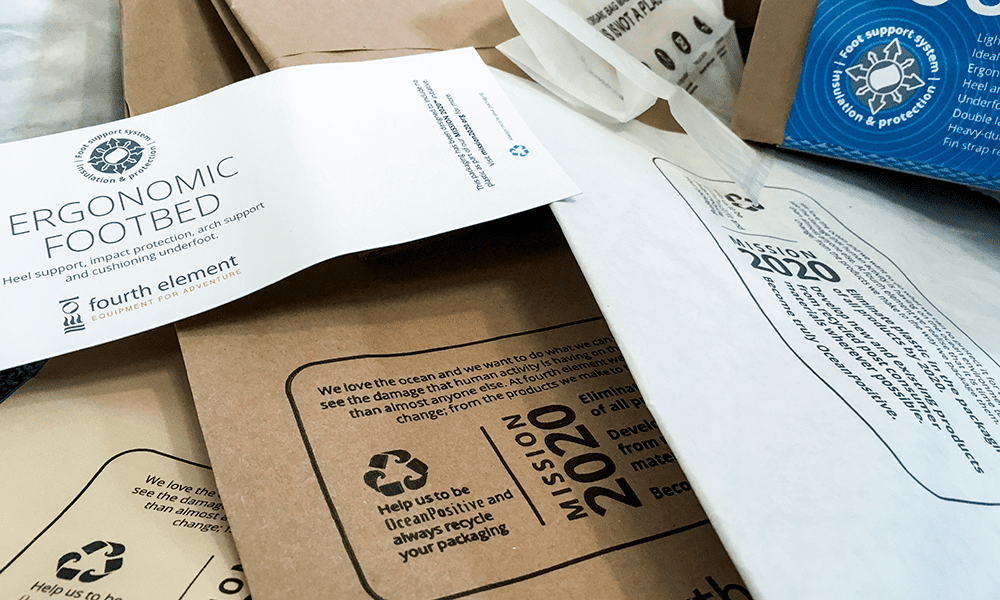

With hand on heart, we couldn’t promote an environmentally positive product, something that’s been made from recycled nylon, and then put it in a plastic bag. Obviously, on one hand, we were doing something that was in some way beneficial, while on the other hand, completely eradicating it. So that made us look more carefully at the packaging. And we have found various, or we have tried various means to package our Ocean Positive swimwear, ways that would be without the use of plastic right down to the Kimball tags and everything.

That’s your swimwear line made from recycled ghost finishing net right?

Yes.

[Note: In 2009 the United Nations Food and Agriculture Organization (FAO) and the U.N. Environment Programme (UNEP) estimated that there were approximately 640,000 tons of abandoned fishing nets in the oceans, accounting for one-tenth of all marine litter.]

What is your timeframe?

Our deadline, our self-imposed deadline, is the World Oceans Day in 2020, by which time our ambition is to be single-use plastic-free from all of our packaging. And it will have taken us the better part of two years to get there. It’s not just a linear progression. We’ve made some leaps ahead, and we’ve changed quite a lot of things already. By the end of this year, we should be almost there, if not all the way there [single-use plastic free]. But I suspect we may have one or two little nuggety ones to solve in the early part of 2020.

And I think again, that’s the sort of message I’d like to put out there to everyone: as much as we all need to change our behavior to reduce the waste of single-use plastic, I think it’s unrealistic to expect individuals and/or companies to change everything overnight and some immediate changes may not be the perfect solution, but steps along the way to achieving a perfect solution and a necessary part of the process.

What are some of the difficulties 4E faced in achieving their plastic-free goals?

I mean there are so many variations, there are so many things to consider in this process. Everybody will have their own challenges, ones that are specific to their company structure and their supply chain. So it’s a multilayered, multi-complex challenge and a huge problem to resolve.

For us, it’s time-consuming, it’s expensive, it’s challenging. Unfortunately, the plastic bag is so good at what it does in terms of protecting a product. It’s clear; you can see the product through the bag. It’s cheap. It’s waterproof, just to name some of the beneficial characteristics of a plastic bag. And it’s incredibly good at doing what you actually want it to do.

The major downfall is that it stays around for hundreds and hundreds of years afterwards. And of course, we’ve seen the result of that in waterways around the world and horrible wildlife footage where you see whales that have been cut open with thousands of these bags inside of them. So trying to find a product, or safe products, that actually replicate the plastic bag is challenging.

What kind of replacements have you found so far?

We have investigated and used bags that are made from vegetable-based or plant-based material. And that works pretty well for a lot of products, for a lot of situations. But it has some limitations. And unfortunately, it’s not a kind of one-stop-shop of going, “oh great, we’ve got a replacement for the plastic bag! However, we do have a plastic bag type thing made from plant material which biodegrades, and it actually will break down in the water, and it can be eaten by a turtle and it doesn’t kill them. It can be digested by sea life. But unfortunately, it has its challenges with temperature, and it can get brittle, and sometimes it can crack. So it doesn’t achieve all of what we need it to achieve.

We’ve used paper bags, we are increasingly using paper bags for our T-shirts, which we then need to label very clearly. And so then, of course, we need to look at a paper-based sticker that is using a glue that is non-toxic. And that’s another little problem to solve.

Every step of the way there seems to be another step or two related to it which is something that needs to be resolved or something that needs to be overcome; whereas your plastic bag is so damn simple. And that is the fundamental problem.

So are there companies working on these problems?

There are companies that are taking the technology a bit further, there are better solutions every day. We are constantly looking at these because we haven’t found the ultimate solution, and they work for some products and not others. Sometimes there are size limitations to what’s possible and sometimes there are cost limitations to what is possible as well. So there are magnitudes of scale and economy like that, which can get quite scary from a cost point of view.

The other challenge is sifting through the actual science, the real science, behind the bags. Because a lot of the bags that are coming out, or at least some, will biodegrade. But they don’t necessarily biodegrade into biomaterial. They biodegrade into small particles of plastic, which is not what we want. The bag ceases to become a bag and it breaks down into little bits of plastic, but that really doesn’t solve the problem at all.

So, not every solution you’ve found solves the problem?

That one solves some element of the problem, that it’s less of a hazard to marine life. But the little bits of plastic will end up getting into the water table and will get into rivers and then end up being flushed out to the ocean. It’s the same way that the microfilaments that washed out of your fabric or your garments when you put them through a domestic washing machine, you’ve got the same fundamental problem there. These little microfilaments of plastic. So it’s pointless replacing a plastic bag with a bag that just breaks down into tiny bits of plastic. So you have got to be careful with regard to what types of solutions you find.

There are some real challenges, and they all take time. But we are getting there. And I think what is really encouraging, and we’re not saying that we’ve solved this problem, but the more little steps that we all take toward achieving the sort of endgame of eliminating single-use plastic, the more solutions that become apparent in the process.

Nice! How do you feel about industry participation in Mission 2020? Has it been well received by the dive industry?

I looked through the list again today to see who has signed up. And I feel really heartened by the fact that a significant number of brands and companies have jumped on board with it and made their commitment to do something different in order to benefit the ocean environment. Obviously, we make quite a few competitive products to some of the brands but it’s really been encouraging to see who has come on board. It’s fantastic that they are seeing the bigger picture.

We’ve got PADI. It was fantastic to get PADI on board. They exert so much influence in the world of diving generally, and they’ve encouraged a lot of their dive centers throughout the world to consider getting involved. GUE has already signed up and is doing the same. It’s fantastic to get major training agencies on board. That creates a great deal of influence amongst the diving industry, the diving market, and people who are involved in diving.

A lot of dive centers have also become involved. We’ve got dive centers that have signed up from Bali to the USA to the UK, virtually globally, and have made a commitment to doing things differently. I’m not exactly sure of the density in the areas that are the most significantly represented, but I was really quite encouraged by how widespread this has actually become.

What challenges do you face with improving the sustainability of your products?

The neoprene that we use in our wetsuits contains between 15 to 20% recycled material from car tires. So it’s an effective recycling process of car tires where 85 % of the car tire is recycled, and the black rubber material is integrated, or is used in the production of the neoprene and accounts for between 15 and 20% of the neoprene that is used in our suits. So again, it’s not the end game, but it’s a step in the right direction.

There is a huge amount of investment going into the reuse and recycle-ability of neoprene. And it may be that the endgame or the ambition of recycling neoprene wetsuits to make more neoprene wetsuits is probably a long, long way off because of the nature of the neoprene once it’s been laminated with the linings inside and out and stitched together etc. And then in order to recycle that material, that suit, there are many processes involved.

And that is one of the biggest impediments and a huge challenge to any recycling process, for when you have mixed materials and mixed construction, it becomes much more challenging to recycle that product. It’s almost impossible to separate different forms of plastic because they have different properties. So that is something, again, in this whole manufacturing process that we’re thinking more about. Like, what we can do to make the product easier to recycle at the end of its life? That’s another thing, going back to wetsuits, I think it’s much more realistic to think of neoprene wetsuits getting recycled for repurposing not as neoprene wetsuits anymore but something else that perhaps requires material similar to neoprene.

How about with your clothing?

Well, basically certain garments shed little microfibers more than others. And it often depends upon how tight-knit that fabric is. And you have a traditional fleece, and the fluffy surface is created by brushing loops, knotted loops of polyester, usually, and breaking them and splitting them and fluffing them up, shall we say. Now that obviously damages these loops and it breaks them and consequently, that is then more susceptible to little fragments breaking off in the washing process. So if you had a garment with the same composition but it’s tightly knitted and hasn’t been brushed, then it sheds fewer filaments.

So a rash guard and swimwear, by the nature of their construction, will shed many, many fewer filaments than a fleece that has been brushed significantly to create a fluffy, soft-feeling texture. Also, there is some evidence that at least suggests that the better the quality of the knit or the better the quality of the fabric, by and large, there is a reduction in the number of filaments that are lost because the knitting process is higher-quality, is a more secure knitting and in effect the garment doesn’t shed its yarn quite as easily. I’m afraid I’ve become a self-confessed fabric geek. I know more about fabric and knitting than I ever wished to know really.

What are the future plans after Mission 2020 has “ended”?

Obviously continued commitment to do what we can do, and hopefully, we will have eliminated single-use plastic from our packaging. I’m pretty confident that we will have achieved that. And part of the Mission 2020 statement is also about our continued quest for using recycled materials in our product range and looking for alternatives to harmful plastics. Some of our products use waterproofing technology which is less chemically toxic. The water runoff is cleaner.

We are actively working with fabric producing fabric knitters that are investing in more sustainable processes in their business. So, basically we will continue to choose a supply chain that minimizes environmental impact over ones that are carrying on as normal, shall we say. It’s about the plastic, in effect, but it’s also about the bigger picture. Therefore, we will continue to invest in and develop less impactful processes in the supply chain and production of our products.

Do you have hope for the future?

Obviously as we are all very aware, elimination of the single-use plastic is a global issue and I’m excited by going online and finding that there’s been a new breakthrough with this or somebody’s investigating this or come up with a technology that may not be the end game, but it’s improving and it’s making progress. We shouldn’t feel like we’ve failed because we haven’t gotten to the end game straightaway.

And what the great thing about all these things is that the more that companies actually look for these products, the more there are manufacturers and companies starting up, creating and selling products to replace plastics. When we started, there seemed to be only one viable option available. I’m sure it wasn’t one, but we found there were very few options in terms of getting something that was like a plastic bag, but not plastic. And now there seem to be more and more alternatives springing up every month.

What about consumers? There are an estimated 500 billion single-use plastic bags used each year by shoppers.

Ultimately, it comes down to consumers because they are one of the most powerful drivers, from a company’s perspective, as we all know. The movement depends on them. Once consumers become aware, take a stand, and actually change their behavior, companies will have to come around. If a company experiences a decline in the sale of a product because aware consumers see little to no effort toward reducing or ending single-use plastic, the company will have to make changes.

And I suppose this is almost a kind of plea or mandate to consumers to think about your choices. Of course, if it costs more to buy the environmental product. And some people may be lucky enough to be able to do that, but many people aren’t. However, we are finding that the price difference between an environmentally friendlier product, whether it’s the way it’s packaged or the way the materials are used, is getting narrower.

As for Mission 2020, it would be great to see the dive industry as a whole adopt this challenge.

Global Underwater Explorers has made a Mission 2020 pledge. At GUE, we pledge to launch an annual GUE Cleanup Event. We feel we can have the greatest impact by utilizing our network of divers in a worldwide cleanup of our waters. We hope to power our office with solar in the near future, will continue to recycle, and eliminate any single-use plastic from our products.

Amanda White is an editor for InDepth. Her main passion in life is protecting the environment. Whether that means working to minimize her own footprint or working on a broader scale to protect wildlife, the oceans, and other bodies of water. She received her GUE Recreational Level 1 certificate in November 2016 and is ecstatic to begin her scuba diving journey. Amanda was a volunteer for Project Baseline for over a year as the communications lead during Baseline Explorer missions. Now she manages communication between Project Baseline and the public and works as the content and marketing manager for GUE. Amanda holds a Bachelor’s degree in Journalism, with an emphasis in Strategic Communications from the University of Nevada, Reno.