CCR

By Divers, For Divers: The iQsub CCR Story

Small Czech company, big impact: how a handful of machinists and divers turned frustration into one of the most trusted CCR brands on the planet.

By Bretislav Vaisar

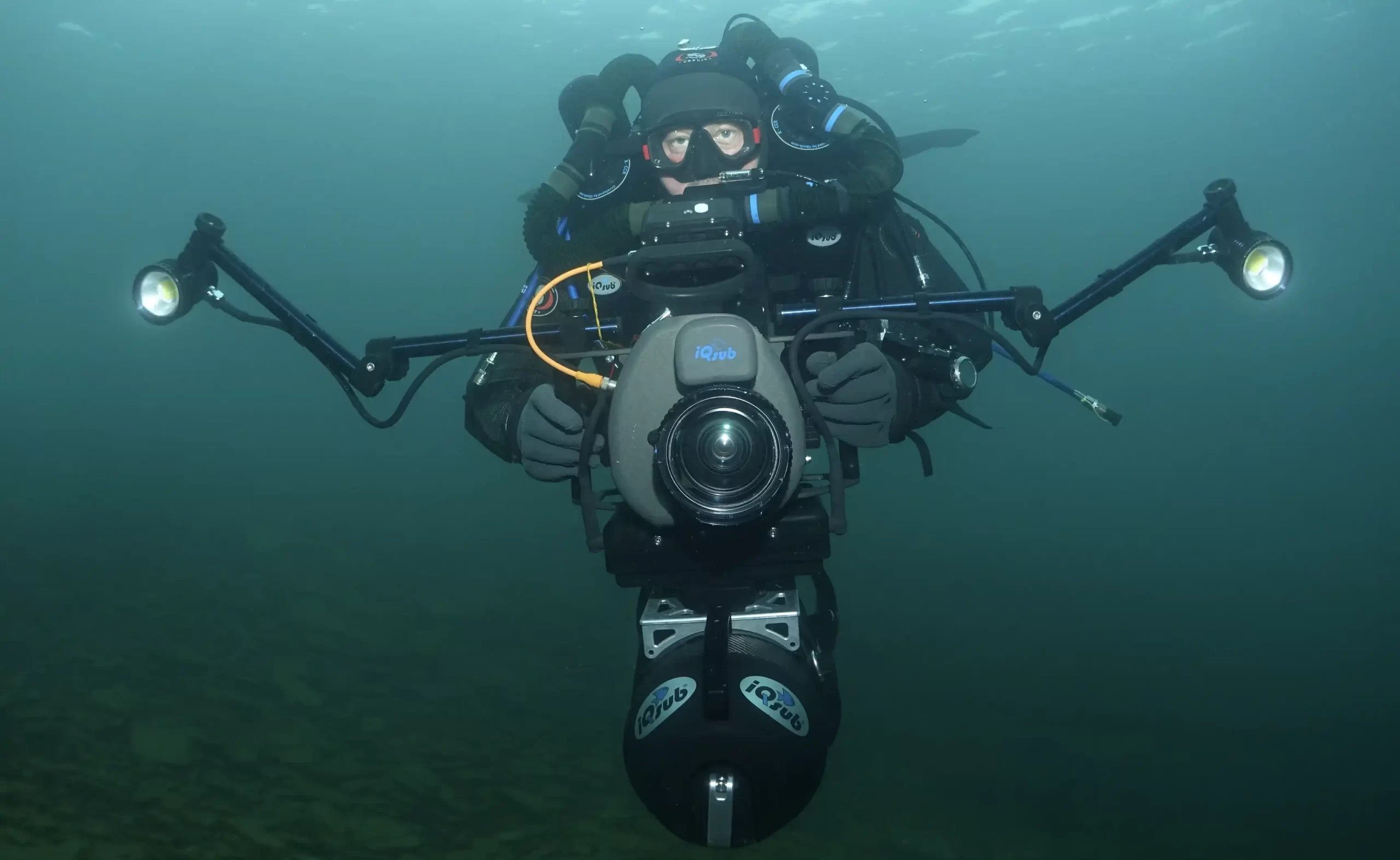

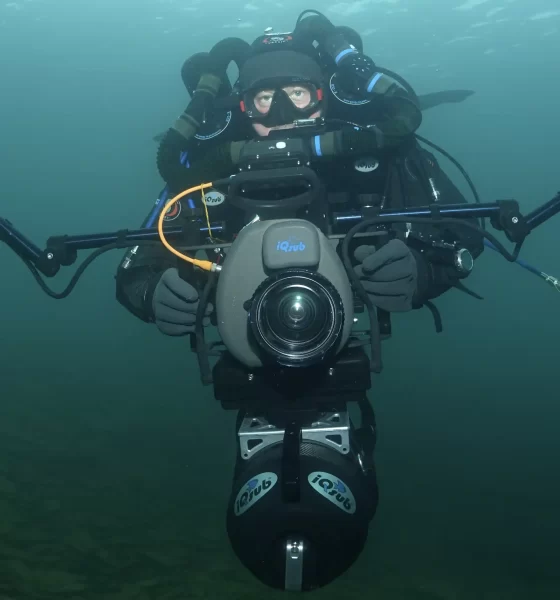

Lead image: Bretislav on the XCCR rebreather

Every innovation story starts with a moment of dissatisfaction. For Bretislav Vaisar, it was around the year 2000, when rebreathers felt more like fragile puzzles than reliable dive partners. A mechanical engineering student and avid diver, he knew he could do better. From flooded quarries and under-ice dives to trimix training in caves and wrecks, Bretislav tested the limits of the equipment available—and found them wanting. Instead of accepting it, he and his team fired up the CNC machines. Out of a workshop in Orlová, Czech Republic, he began cutting housings, welding frames, and building prototypes that matched the dives he wanted to do. By 2005, he had designed his first CCR. Two decades later, his company, iQsub, is producing a family of CE-certified units—XCCR, FLEX2, and FX—that have traveled from French and Floridian caves to Bikini Atoll.

This article traces the path from stubborn diver to global CCR innovator, exploring how Bretislav and his small team turned “we can do better” into machines that instructors, explorers, and filmmakers now trust at depth.

In Orlová, a small town in the Czech Republic, a group of divers decided they’d had enough. If the market couldn’t deliver what they wanted, they would build it themselves. The company’s first years weren’t about breathing loops at all, but about machining rugged underwater housings, reels, and lights. Even then, the DNA was clear: function first and built for water, not showrooms.

That simple but radical idea—by divers, for divers—became the seed of iQsub.

A First Experiment: The Mentes

By 2005, iQsub rolled out its first eCCR, the Mentes. It wasn’t mass-produced—only a few dozen were made—but it marked the company’s entry into life support. With Hammerhead electronics, a radial scrubber, and the custom-made Vario BOV, the Mentes was less a commercial success than a statement of intent.

At DEMA the following year, the fledgling rebreather caught wider attention. A partnership with Juergensen Marine brought Hammerhead electronics together with iQsub’s hardware and, soon, the small Czech shop found itself assembling and distributing Hammerhead CCRs in Europe and Juergensen Marine for the rest of the world.

Four Hammerhead at a quarry

Building Blocks: Shrimp and FLEX

From there, the designs matured. In 2010 came the Shrimp BOV, a compact, ball-valve bailout that spread quickly through the CCR community. Two years later, iQsub launched the FLEX CCR, a sidemount unit designed for the exploding cave and travel scene. Divers appreciated the compactness and robust build, but the reliance on Hammerhead electronics loomed as a problem. Supply delays, certification headaches, and dated firmware threatened to cap iQsub’s ambitions.

A Breakthrough with Shearwater

The real turning point arrived in 2014. Determined to move beyond Hammerhead, iQsub began sketching out a new rebreather—the machine that would become the XCCR. The concept was unapologetically ambitious: an expedition-grade, CE-certified CCR that would hold its own in the most hostile environments. After experimenting with other vendors in 2015, the breakthrough came when iQsub teamed up with Shearwater Research. By 2016, prototypes of the XCCR were running DiveCAN electronics with digital HP sensors, optional CO2 monitoring, hermetically sealed connectors, and full “black box” data logging. The package looked like nothing else in Europe at the time: a backmount CCR built not only for deep caves and wrecks, but with the redundancy and safety features to satisfy auditors and expedition leaders alike.

In 2017, the first production units shipped. In a move that still gets mentioned in diver circles, iQsub swapped out entire electronic heads—controllers, HUDs, and all—for early adopters, free of charge. By 2018, the XCCR earned CE certification under EN 14143:2013 without modifications. For a Czech manufacturer, it was a milestone that placed them on equal footing with the giants.

The Family Expands: FLEX2 and FX

The success of the XCCR didn’t pull iQsub away from sidemount. Instead, it sharpened their focus. In 2017 the FLEX2 arrived, redesigned with 3D counterlungs, an integrated ADV, and Shearwater brains. The unit quickly found its way into caves and mines across Europe—and won over instructors who valued its compact size, easy maintenance, and ruggedness.

Then came the FX CCR. Development started around 2022 with a clear target: Build a rebreather small enough for carry-on travel yet tough enough for mixed-gas dives. The chest-mounted FX tipped the scales at just 11 kg/24 lb, earned CE approval by early 2025, and still carried divers to 100 m/330 ft on trimix. Suddenly, CCR wasn’t just for expeditions with crates and sherpas—it was a legitimate travel companion.

The iQsub CCR Family

Together, these three machines form the backbone of iQsub today. The XCCR stands as the workhorse expedition unit: backmounted, heavy-duty, and built for depth, cold, and redundancy. The FLEX2 is its sidemount sibling, slim enough for narrow cave passages but still bristling with Shearwater tech. And the FX CCR is the newcomer, a chest-mount designed to fit into overhead bins but still dive trimix to 100 m/330 ft.

Between them, iQsub now covers the full spectrum: expedition, sidemount, and travel. For a company that started with camera housings, the arc is remarkable.

The Uniqueness of iQsub

What makes iQsub stand out isn’t just its Czech precision machining or the fact that its founder dives the very gear he designs. It’s the consistency of a vision carried through more than two decades of in-house development. For over 20 years, the company has designed and built its CCR units under one roof, refining every screw, bayonet fitting, and sensor housing until it met their own standards in the water.

Today, iQsub offers three CE-certified units covering the full spectrum of configurations—backmount, sidemount, and chestmount. Each carries the same DNA: an easily removable sensor cartridge that allows divers to dry, check, or replace O2 sensors without hassle; a user-friendly design that can be assembled or maintained on the spot, even in field conditions; and a reputation for being exceptionally durable. These are expedition-grade machines built to take the punishment of flooded caves, cold wrecks, and long decompression slogs while still being intuitive enough for divers to manage under stress.

In an industry often accused of making things more complicated than they need to be, iQsub has earned a reputation for doing the opposite—turning complexity into elegance and fragility into reliability.

Design in Dialogue with Divers

What makes iQsub’s units distinctive isn’t just the machining or the electronics—it’s the way each innovation traces back to a diver’s request. FLEX users wanted a dedicated sidemount BOV; the Shrimp SM BOV Neo was born. Explorers asked for faster cleaning and assembly; bayonet fittings spread across the loop. Instructors called for easier maintenance; removable sensor cartridges and accessible counterlungs followed.

All three CCRs share a design language: radial scrubbers for long endurance, Shearwater DiveCAN controllers with Petrel 3 handsets, HUDs and optional NERD2 displays, dual independent batteries to split solenoid and HUD power, and tool-free bayonet connectors throughout. These aren’t gimmicks; they’re lived solutions to problems faced in caves, mines, and oceans.

Inside the Orlová Workshop

The heart of iQsub beats in a facility tucked into the green outskirts of Orlová. Step inside and it’s all precision: CNC mills and lathes, TIG welders, sand-blasters, laser markers, assembly benches, and a pressure chamber rated to 330 m/1,083 ft. Every part—Delrin, stainless steel, titanium, anodized aluminium, brass—is designed in CAD, programmed via CAM, and cut in-house.

The shop runs under ISO 9001:2015 certification, but what matters more is its obsessive cycle of building, testing, and re-testing. New parts are dunked in salt water, chilled to 4 °C/39.2 °F, and hammered at depth before they ever make it into production. Only then do they move to CE certification in Germany. The result is gear that looks clean but feels battle-ready.

From Caves to Atolls

It’s one thing to build rebreathers. It’s another to see them used in the kind of dives that make history. iQsub’s machines have gone into the Mexican caves on film projects with Paralenz and surveyed wrecks for Heritage Malta. They’ve carried explorers beyond 200 m/656 ft in deep European caves, into the bomb-scarred lagoons of Bikini Atoll, Britannic, and through miles of flooded mine passages.

Culture and Ethos

Despite its global reach, iQsub remains a small workshop team. The atmosphere is friendly, collaborative, and stubbornly hands-on. Ideas don’t sit in management decks—they move straight from divers to machinists to prototypes. The guiding principle hasn’t changed since day one: Make gear that’s attractive, user-friendly, robust, and reliable enough that the people who build it want to dive it themselves.

Looking Forward

Where does the company go next? The trajectory suggests two parallel paths. One is toward smaller, lighter systems that make CCR truly portable, embodied by the FX CCR. The other is toward smarter, safer electronics, with solid-state oxygen sensors already in development alongside Shearwater. Meanwhile, iQsub continues to machine new housings for action cameras, applying the same obsessive attention to detail that shaped their rebreathers.

In an industry often accused of moving slowly, iQsub shows what’s possible when divers take matters into their own hands. From housings to expedition CCRs, from sidemount caves to chestmount carry-ons, the company has spent 25 years proving a point: When you build for real dives, the rest follows.

Timeline: Milestones in iQsub’s Journey

- 2005: First prototype, the Mentes CCR, hits the water

- 2010: Shrimp BOV debuts, quickly spreading across the CCR community

- 2012: The FLEX CCR brings sidemount rebreathing into focus

- 2016: XCCR prototypes emerge with Shearwater DiveCAN electronics

- 2017: FLEX2 CCR launches with redesigned counterlungs and Shearwater brains

- 2018: XCCR earns CE certification under EN 14143:2013

- 2023: FLEX2, a sidemount unit, achieves CE certification

- 2025: FX CCR, a chest-mounted travel unit, achieves CE certification.

Testimonial on Using the XCCR Rebreather

by Joanna Wyrebek

I’ve been diving the XCCR since 2018, taking it everywhere from wrecks in Narvik’s icy depths to long mine penetrations. It has never let me down. Built tough and performing flawlessly, it’s become my most trusted piece of kit. For expedition dives, I rely on the heavier XCCR version—its durability and capacity make it indispensable. But for travel, I switch to a lighter setup with a smaller scrubber and 2-liter tanks. Even then, I still get 4 hours underwater, with the same reliability in a more compact form. The XCCR’s thoughtful design, Shearwater electronics, and straightforward maintenance stand out. Its modular flexibility—different canisters, scrubbers, and counter lungs—means it adapts to any dive, from extended technical expeditions to quick trips abroad. Diving, for me, is a journey into history and the unknown. The XCCR has been central to that journey, giving me the confidence to push further and deeper. I recommend it to anyone ready to take their diving to the next level.

IQsub Instructors & Ambassadors

Names like Joanna Wyrebek, Dave Gration, Randy and Josh Thornton, Rasmus Dysted, Anton Zhuchkov, and Laurent Boulmier surface again and again in these stories. They’re not just instructors—they’re test pilots proving that the hardware holds up when dives get serious.

Anton Zhuchkov

Anton Zhuchkov is a leading cave explorer and speleologist with thousands of hours underwater on some of Europe’s deepest dives. A designer of advanced diving gear and ROVs, Antone is also an Instructor Trainer and member of the IDF Training Council. Based in Portugal, Anton focuses on teaching advanced CCR techniques for cave exploration and represents iQsub on the Iberian Peninsula.

Dave Gration

With over 40 years in diving, Dave Gration is an Instructor Trainer and deep wreck specialist. His career includes dives on legendary wrecks such as the Britannic and Lusitania, and he has served as a Diving Safety Officer for institutions like the University of Malta. Renowned for his expertise in deep-water logistics and archaeology, Dave continues to push the limits of safe exploration.

Laurent Boulmier

Based in southern France, Laurent Boulmier is a professional diver with 36 years of experience. A TDI Instructor Trainer on iQsub rebreathers, he is passionate about deep wreck and cave exploration. His latest project revisits the WWII wreck L’Heureux, lying 120 m/393 ft deep off of Monaco.

Rasmus Dysted

Founder of Technical Diving Courses, Rasmus Dysted has been teaching since 1994 and is among the world’s highest-certified Instructor Trainers. With a career spanning shop ownership, course development, and consulting for equipment manufacturers, he remains active in global expeditions and exploration.

Josh Thornton

Josh Thornton is a technical diving instructor with a passion for cave exploration on rebreathers. When not underwater, he enjoys the outdoors—mountain biking, skiing, climbing, and spending time with his family, including his three future dive buddies.

Joanna Wyrebek

Joanna Wyrebek is a UK-based CCR Cave and Full Trimix diver originally from Poland. A co-founder of The Cavettes, she champions women in technical diving and is active in ocean conservation projects. Joanna specializes in wrecks and flooded mines and proudly represents iQsub as a brand ambassador.

Enjoyed this read? Here are more stories that tie into it.

DIVE DEEPER

InDEPTH: SF2 – The Good, the Bad, the Beautiful by Jens O. Meissner and Helmut Spangler (2024)

InDEPTH: mCCR Face-Off: Gemini vs Sidewinder By Grant Tobin (2023)

InDEPTH: Whole Lotta CHO2ptima Going On By Michael Menduno (2022)

InDEPTH: Introducing the Shark Rebreather (hCCR) by Michael Fineschi and Benoît Jadot (2025)

InDEPTH: Introducing the Generic Breathing Machine (GBM) By Larry Cohen (2025)

InDEPTH: The DIVE TALK GO—A Rebreather for Everyone by Gus Gonzalez (2025)

Bretislav Vaisar is the founder and owner of iQsub Technologies, based in the Czech Republic. A graduate of the Faculty of Mechanical Engineering at Brno University, he combined his academic background with a lifelong passion for diving to become one of the most innovative engineers in the closed-circuit rebreather field. In the 1990s, he launched V&C, a company supplying components for diving equipment manufacturers, and completed advanced training as an IANTD Full Trimix and Full Cave diver as well as an EANx Instructor, CCR Full Trimix Instructor, XCCR Instructor Trainer, FLEX2-CCR Instructor, and FX-CCR Instructor. Bretislav’s hands-on diving—ranging from flooded quarries and under-ice explorations to deep caves, wrecks, and open seas—inspired him to design equipment that could withstand the harshest environments. In 2000, he founded the iQsub brand, opening a dive shop and producing underwater housings for video cameras before turning to life-support systems. By 2005, he had developed his first CCR using Hammerhead electronics, later collaborating with Juergensen Marine to manufacture hundreds of Hammerhead units. As chief designer at iQsub, Bretislav has since overseen the development of the FLEX CCR in 2012, the XCCR in 2014, the FLEX2 in 2017, and the FX CCR in 2022. He continues to dive regularly on iQsub units, testing his designs in the same environments they were built for.